Marketplace

-

kg-

€-

kgEnd-of-arm Accessories

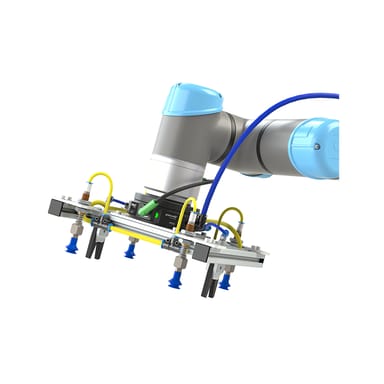

End-of-Arm Accessories play a key role in modern automation across a wide range of industries. Robots and automated systems are used to speed up processes and ensure consistent, reliable results. With components such as tool changers, sensors, and other end-of-arm tools, production workflows can be optimized, enabling efficient and high-quality automation solutions.

What Are End-of-Arm Accessories?

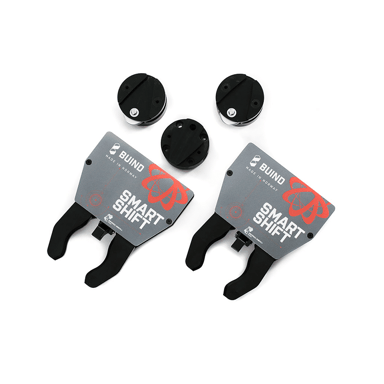

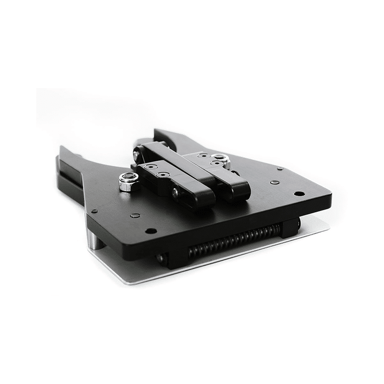

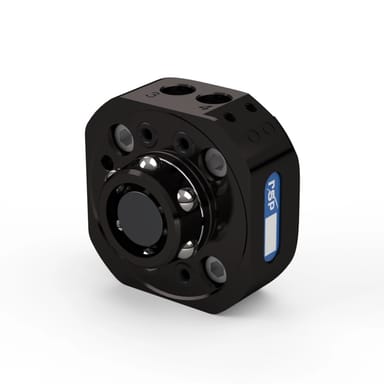

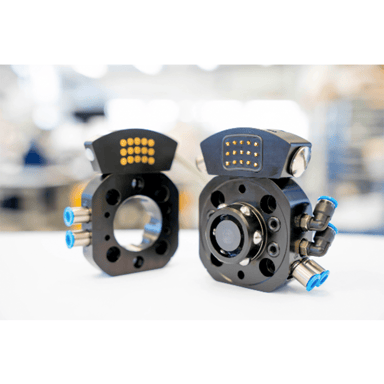

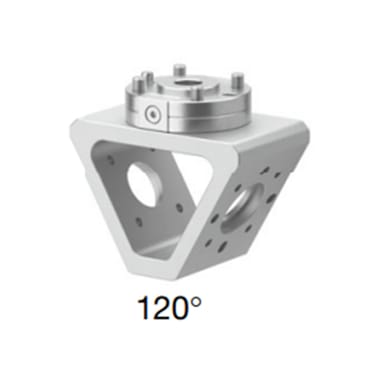

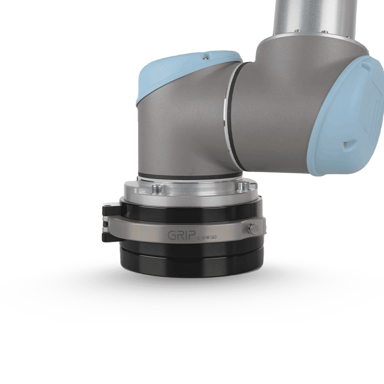

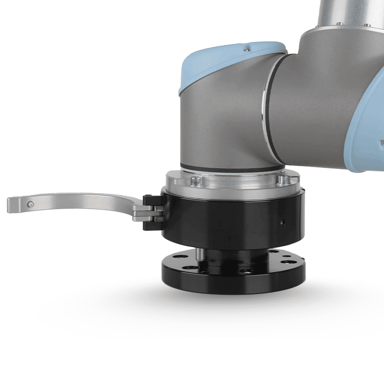

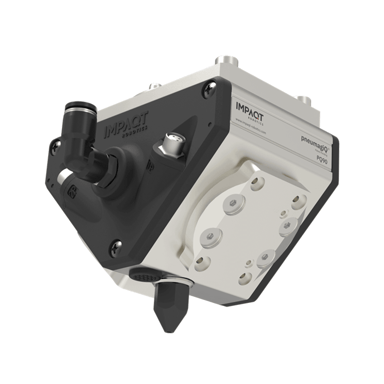

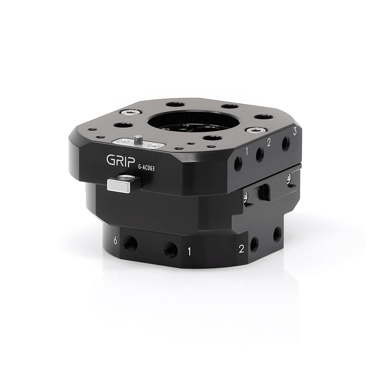

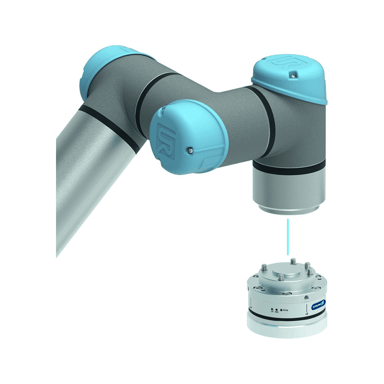

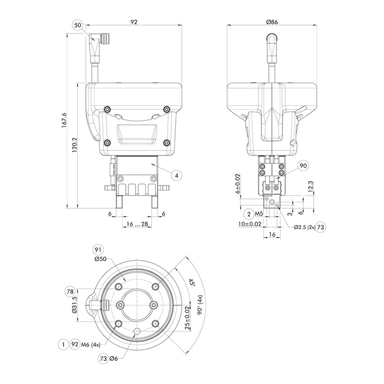

End-of-Arm Accessories are essential components in modern robotics and automation. They refer to the wide range of tools and devices attached to the end of a robot arm — including tool changers, sensors, grippers, and force-torque units. These accessories extend a robot’s capabilities, allowing it to perform tasks such as picking, measuring, assembling, or testing with precision and consistency.

By equipping robots with the right combination of end-of-arm tools, companies can adapt automation systems to specific applications, making production lines more flexible and efficient.

Applications Across Industries

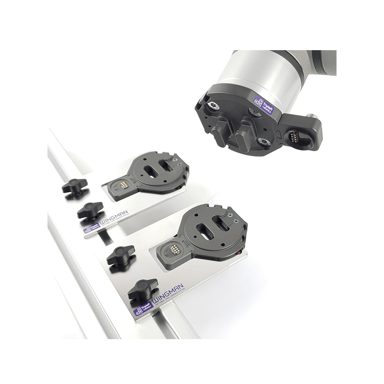

End-of-arm accessories are used in nearly every sector where automation plays a role — from manufacturing and assembly to logistics, packaging, and quality inspection. In metalworking, quick tool changers allow robots to switch between machining or polishing tasks in seconds. In electronics or automotive production, precision sensors ensure accurate placement and alignment. In food and pharmaceutical environments, specialized grippers enable hygienic handling and reduce contamination risks.

Their modular design makes them suitable for both industrial robots and collaborative robots (cobots), supporting everything from repetitive high-speed operations to delicate, human-assisted tasks.

Benefits of Using End-of-Arm Accessories

The integration of end-of-arm tools brings several advantages to automated systems:

- Greater flexibility – Robots can be quickly adapted for different processes or products.

- Improved precision – Sensors and force-feedback systems enhance accuracy and quality control.

- Reduced downtime – Tool changers enable fast reconfiguration between tasks.

- Increased productivity – Automated tool handling shortens cycle times and minimizes manual intervention.

- Enhanced safety – Smart sensors and compliant grippers make robot-human collaboration safer and more predictable.

These features make end-of-arm accessories a key factor in achieving scalable and cost-efficient automation.

Integration and Compatibility

Modern end-of-arm accessories are designed for easy integration with common robotic platforms. Manufacturers such as OnRobot, Schunk, Robotiq, and Zimmer Group offer systems compatible with major robot brands, including Universal Robots, FANUC, KUKA, and ABB. Standardized mounting interfaces and plug-and-play setups allow for quick installation without extensive custom engineering.

In addition, many accessories come with software plugins that simplify programming and configuration directly through the robot’s control interface — making it easier than ever to deploy advanced automation solutions.

The Role of End-of-Arm Accessories in Modern Automation

As automation continues to evolve, end-of-arm tooling remains a driving force behind its progress. These accessories bridge the gap between mechanical motion and real-world interaction — enabling robots not only to move but to sense, adapt, and perform tasks with human-like precision.

Whether for small-batch production, flexible manufacturing, or collaborative environments, end-of-arm accessories make robotic systems more capable, adaptable, and efficient — setting new standards for the next generation of automation.

Find your automation solution now with our configurator