Marketplace

-

€-

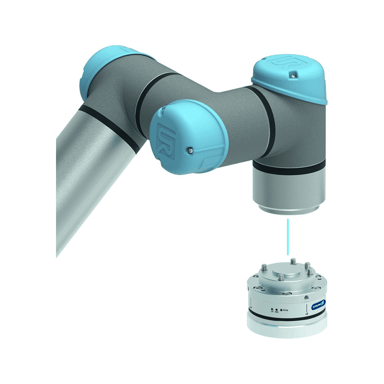

kgForce Torque Sensors

Force Torque Sensors measure the force and torque applied to a robot’s tool or gripper, enabling precise control and sensitive handling. They improve accuracy, ensure consistent quality, and allow robots to perform delicate or contact-based tasks safely and efficiently.

What Are Force Torque Sensors?

Force Torque Sensors are advanced measurement devices that detect the amount of force and torque applied at a robot’s wrist or end effector. They provide real-time feedback about the physical interaction between the robot and its environment, allowing for precise, adaptive, and safe motion control. By capturing forces along multiple axes, these sensors help robots perform delicate, contact-sensitive tasks with high accuracy — something that traditional position-based control cannot achieve.

Applications in Robotics and Automation

Force torque sensors are used across many industries where precision and sensitivity are essential. In assembly and manufacturing, they enable controlled insertion, tightening, or polishing operations. In quality inspection, they detect variations in pressure or alignment that could indicate defects. In collaborative robotics (cobots), they play a vital role in ensuring safe human-robot interaction, detecting unexpected contact and adjusting motion instantly.

Typical applications include:

- Surface finishing and polishing

- Precision assembly and screwdriving

- Force-controlled insertion and fitting

- Contact-based quality inspection

- Research and development testing setups

Benefits of Force Torque Sensors

Integrating a force torque sensor brings measurable improvements to robotic performance and process reliability:

- Enhanced precision – Accurate force control ensures consistent results in demanding operations.

- Improved safety – Real-time feedback allows for automatic collision detection and softer interaction.

- Higher quality – Constant force monitoring helps maintain even pressure and reduce product defects.

- Adaptability – Robots can adjust their behavior dynamically based on sensor feedback.

- Ease of integration – Many models offer plug-and-play compatibility with major robotic platforms.

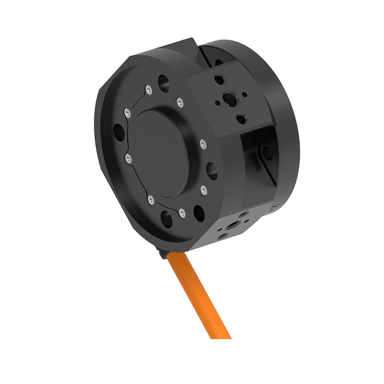

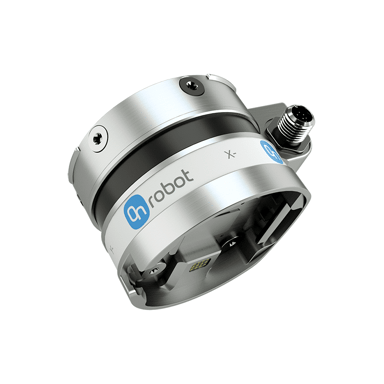

Compatibility and Integration

Modern force torque sensors are designed to work seamlessly with leading robot brands such as Universal Robots, KUKA, FANUC, ABB, and Yaskawa. Manufacturers like OnRobot, ATI Industrial Automation, and Robotiq provide sensors that integrate directly through standard interfaces and software plugins, simplifying installation and setup.

These systems support a range of communication protocols and calibration tools, ensuring that users can quickly fine-tune their robots for optimal performance across different applications.

The Role of Force Torque Sensors in Modern Automation

As automation grows more advanced, force torque sensing has become a key technology for achieving true robotic dexterity. It enables robots to handle sensitive or variable tasks with a level of precision previously limited to human operators. From fine mechanical assembly to delicate material handling, force torque sensors turn ordinary robotic systems into responsive, intelligent tools capable of adapting to real-world conditions — driving the next step in industrial automation.

Find your automation solution now with our configurator