Marketplace

-

€-

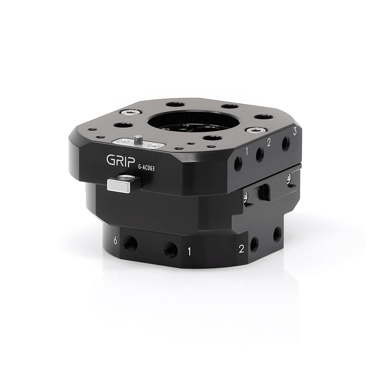

kgTool Changers

Tool Changers allow robots to quickly and automatically switch between different end-of-arm tools. They increase flexibility, reduce downtime, and enable seamless transitions between tasks such as gripping, welding, or assembly in automated production environments.

What Are Tool Changers?

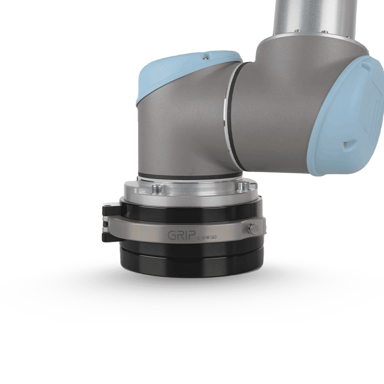

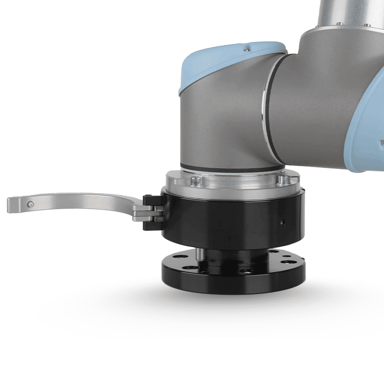

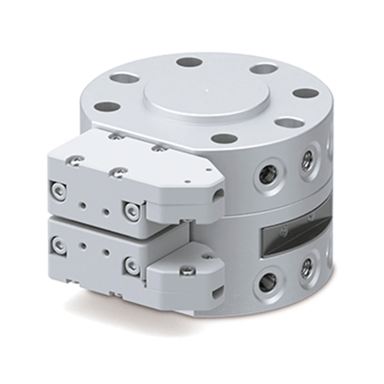

Tool Changers are key components in modern robotic and automation systems, designed to enable robots to automatically switch between different end-of-arm tools. This allows a single robot to perform multiple tasks — such as gripping, welding, screwing, or measuring — without manual intervention. By eliminating the need for human tool changes, they significantly reduce downtime and increase production flexibility.

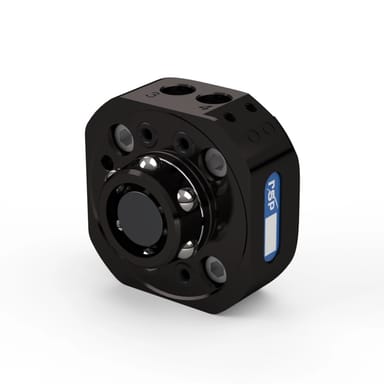

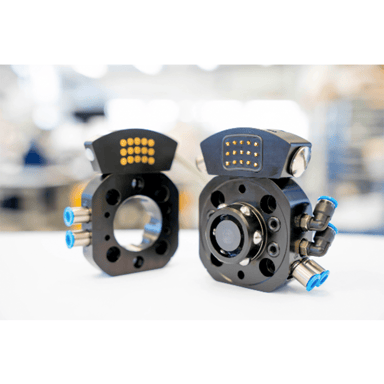

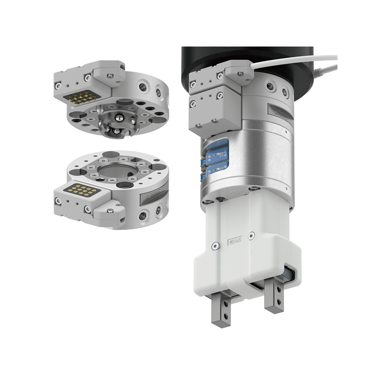

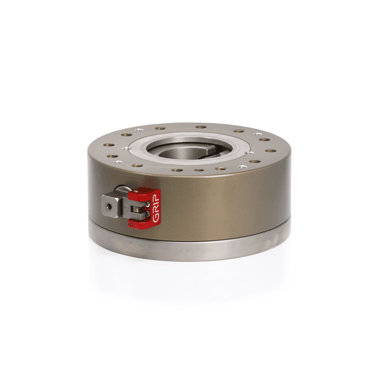

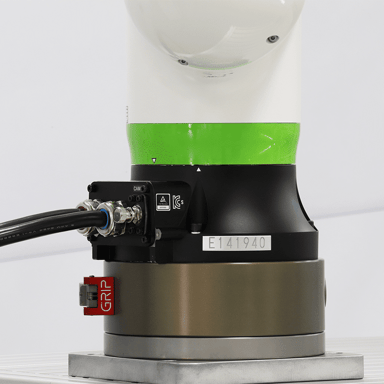

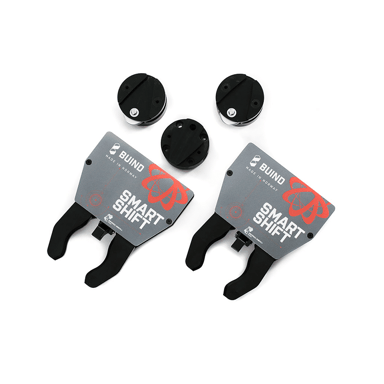

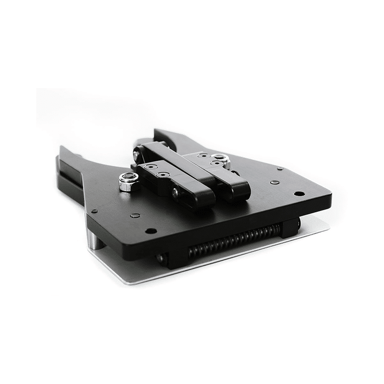

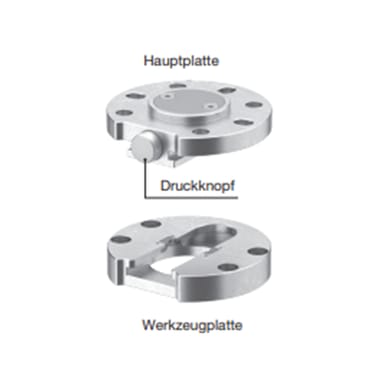

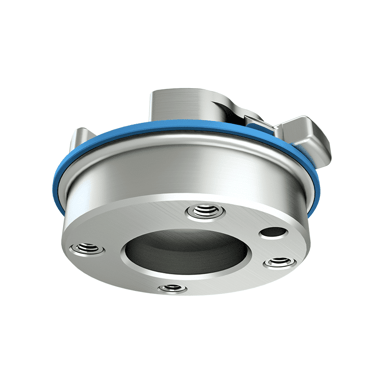

Tool changers consist of two main parts: a robot-side coupling and a tool-side coupling. These connect and disconnect mechanically, pneumatically, or electrically, allowing for a secure, repeatable, and fast exchange of tools within seconds.

Applications in Industry

Tool changers are used across a wide range of industries and applications, from high-speed manufacturing to collaborative robotics. In automotive and metalworking, they allow robots to move seamlessly between machining, deburring, and assembly. In electronics and packaging, they enable quick transitions between different grippers or end effectors, improving workflow efficiency. Even in laboratory automation or R&D, tool changers support setups where multiple specialized tools are required for varied experiments or testing processes.

Benefits of Using Tool Changers

Integrating a robotic tool changer offers multiple advantages that boost efficiency and system performance:

- Increased flexibility – One robot can perform several operations without manual reconfiguration.

- Reduced downtime – Automatic tool changes speed up production cycles.

- Higher precision – Repeatable connections ensure consistent accuracy in each tool exchange.

- Lower costs – Maximizing robot utilization reduces the need for additional equipment.

- Improved safety – Automated coupling eliminates manual handling in high-risk environments.

These features make tool changers especially valuable in multi-process automation, where versatility and uptime are critical.

Compatibility and Integration

Modern tool changers are designed for easy integration with a wide variety of industrial and collaborative robots. Manufacturers like OnRobot, Schunk, Zimmer Group, and Robotiq offer standardized systems compatible with popular brands such as Universal Robots, FANUC, KUKA, ABB, and Yaskawa.

Many models support electrical and pneumatic connections, allowing for power, air, and data transfer directly through the coupling. This ensures smooth operation and reliable communication between the robot and its tools.

The Role of Tool Changers in Modern Automation

As automation systems evolve toward greater efficiency and flexibility, tool changers have become an essential component of modern production setups. They enable robots to adapt dynamically to different processes, increasing system versatility while maintaining high precision and reliability. Whether in high-volume manufacturing, flexible small-batch production, or collaborative workspaces, tool changers help maximize productivity and unlock the full potential of robotic automation.

Find your automation solution now with our configurator