Marketplace

-

€-

mm-

mm-

kgCameras

Industrial cameras power vision in automation, enabling detection, inspection, and precise positioning. From 2D to 3D systems, they drive accuracy, efficiency, and intelligence across automated processes.

What Are Industrial Cameras?

Industrial Cameras — also known as machine vision cameras — are specialized imaging devices designed for use in automated production and robotics. They capture visual data used for inspection, measurement, object recognition, and guidance, helping robots and machines make data-driven decisions.

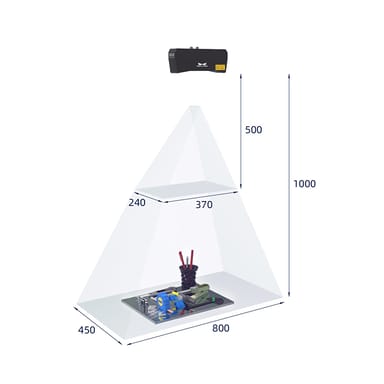

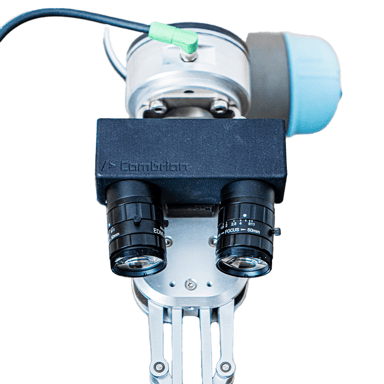

Depending on the application, these cameras can be 2D, 3D, or smart vision systems with integrated processing and AI-based analysis. Their ability to interpret the environment transforms automation from simple motion control into intelligent, adaptive operation.

Applications in Automation and Robotics

Industrial cameras are used in nearly every automation and manufacturing sector, including:

- Quality inspection – detecting defects, surface flaws, or assembly errors

- Pick-and-place robotics – locating and identifying parts for accurate handling

- Measurement and positioning – supporting precise alignment and calibration

- Sorting and packaging – differentiating items by shape, color, or barcode

- Safety and monitoring – verifying correct component placement or process completion

By integrating camera systems into robotic workflows, manufacturers achieve greater precision, reduced waste, and higher overall efficiency.

Benefits of Using Cameras in Automation

- High accuracy – Visual feedback ensures exact object positioning and quality control

- Process optimization – Enables automated decision-making and real-time adjustments

- Versatile applications – Suitable for 2D inspection, 3D measurement, or AI-driven analysis

- Reduced human error – Automated vision replaces subjective manual inspection

- Improved traceability – Visual data supports documentation and process validation

These advantages make cameras indispensable in achieving reliable, intelligent automation across industries.

Integration and Compatibility

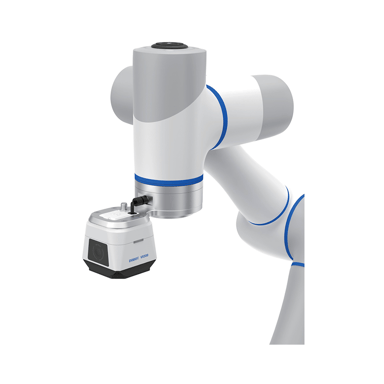

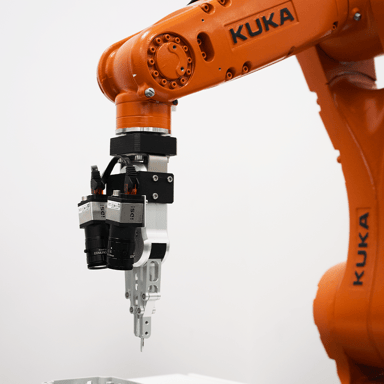

Modern industrial cameras integrate easily with robotic systems, PLCs, and control software. They support standard communication protocols such as Ethernet/IP, PROFINET, and GigE Vision, ensuring compatibility with major automation brands like Universal Robots, FANUC, ABB, and KUKA.

Manufacturers such as Cognex, Keyence, Basler, and SensoPart provide camera solutions for both fixed-mount and robot-mounted applications. Smart cameras with onboard processing simplify setup and reduce system complexity, while 3D cameras enable advanced perception for complex handling tasks.

The Role of Cameras in Modern Automation

In smart manufacturing and robotics, cameras serve as the “eyes” of the system — turning mechanical motion into intelligent action. They enable robots to see, identify, and adapt, ensuring higher accuracy and flexibility even in dynamic environments.

Whether used for inspection, guidance, or measurement, industrial cameras are central to quality-driven and efficient automation. As vision technology continues to evolve, they are paving the way for fully autonomous and adaptive production systems.

Find your automation solution now with our configurator