Marketplace

ROI Calculator

€11,000.00 excl. VAT.

From 1.000,00 € a month with lease buy or installment.

- Specifications

- Overview

- Description

- Downloads

- FAQ

- Similar products

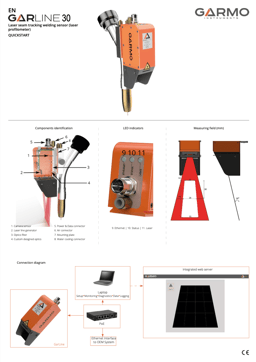

GarLine surpasses the IP67 insulation grade and successfully performs in a 0ºC/ 70ºC working range. Its original design incorporates materials for aerospace use that ensure an optimal EMI insulation, including TIG welding processes

Its electronics of 4 parallel processes of 4Gb of RAM computes the corrections at 42 images per second in full resolution. Besides, GarLine includes an innovative feature for dynamic adaptation of sensor and laser parameters between frames, to correct reflection problems in applications involving varying material surface conditions.

What makes GarLine sensors different is the inclusion of a connection system adapted to the new IoT technology. The sensor supports most of TCP/IP protocols, and the web interface eliminates the need of specific software.

The new GarLine sensors are designed to offer easy integration, to both PLCs and Cobots. For the first time, only one wire is required for a complete integration. No more computers, nor other devices needed. Just a POE switch injector.

Featured on Unchained TV

Unfortunately, there are no use case videos yet for this product. Browse other robotics videos on Unchained TV.

| Specifications | ||

|---|---|---|

| Field of view | 28 cm² | |

| Min. Operating Distance | 10 mm | |

| Max. FPS | 42 | |

| IP classification | IP 67 | |

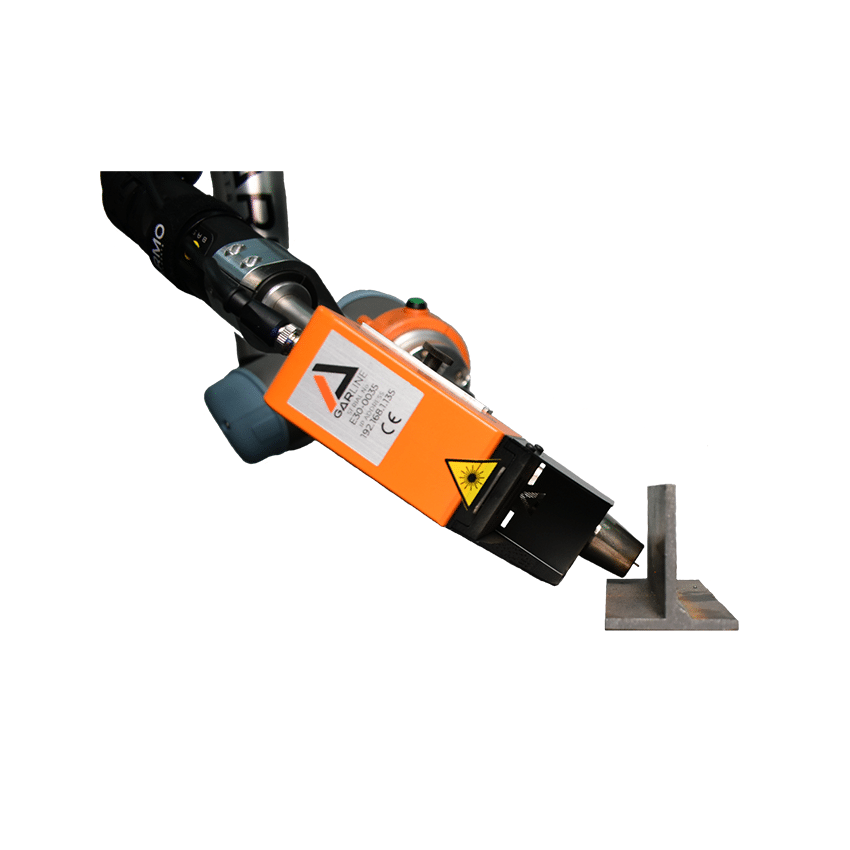

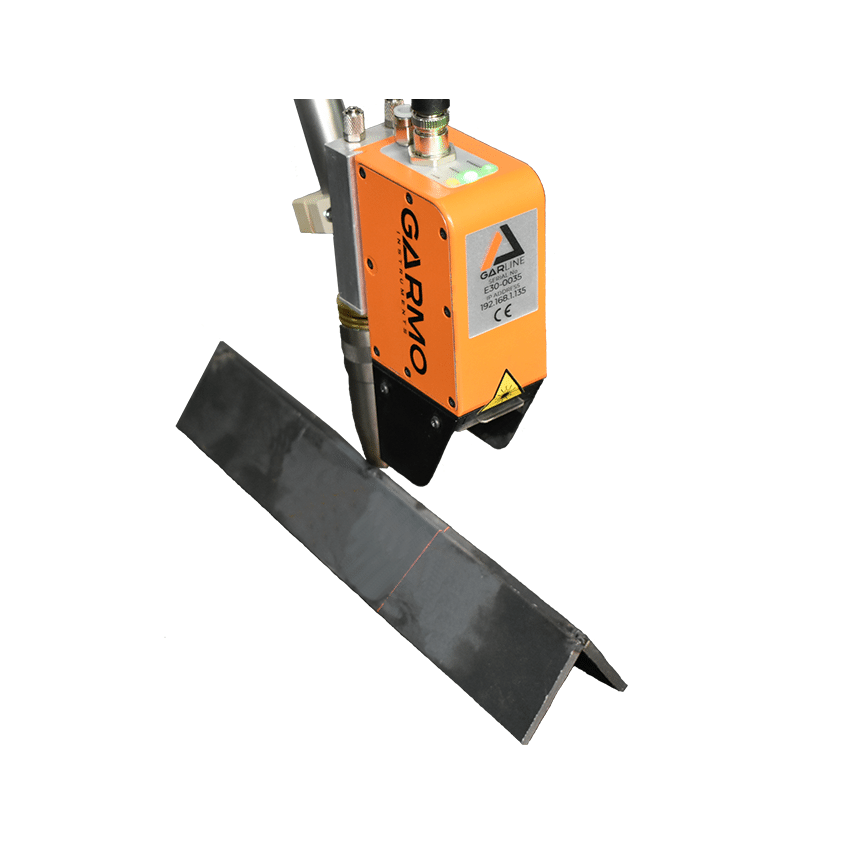

GARMO GarLine C is the new seam tracking sensor for automated welding with cobots. This innovative seam tracking laser sensor with integrated software offers a set of unique capabilities to simplify operation and improve weld quality while also increasing performance in welding processes. GARMO GarLine C is specially designed for the most adverse working environments and reliably handles smoke, humidity, corrosion, and welding spatter. The sensor is resistant to magnetic fields, and its outer housing withstands both shock and hard impact.

Convenient software integration with Universal Robots and Fanuc cobot interfaces allows for the easy and intuitive setup of welding processes from the cobot operator interface. Automated seam detection means the operator doesn't even have to manually teach exact points with the cobot! Real-time tracking of the seam ensures precise tracking of the welding device at all times and thus also optimum weld quality - even if the tolerance of the robot arm increases with age.

In addition, the use of a single standard cable (for power and data) simplifies sensor installation and ensures a consistent connection. The sensor comes with several easily replaceable disposable protective windows and a calibration plate for cobots from Universal Robots.

Download the GARMO GarLine C datasheet (EN) here!

Download the GARMO GarLine User Manual (EN) here!

Download the GARMO GarLine C STEP File here!

To place an order, send us an inquiry through the button at the top of the page or contact us through the chat.

Unchained Robotics is the biggest marketplace for all things automation. We have over 36 brands with 9 different categories such as Cobots, Grippers, Cameras, Starter-kits, End-of-Arm-Accessories, Teaching-kits, Turnkey Solution, Cobot-Base and even

Services. For more information, check out our About page.

We have the answer for you in a series of blog post below:

Was du bei der Auswahl eines Cobots beachten solltest – The Specs that Matter

The Specs that Matter Die Top 10 Fragen zur Roboterwahl

Talk to an Automation expert

Have questions about this product, pricing, or your automation projects? Fill out the form and an automation expert from our team will be in touch within 24 hours.

Sebastian Hren

Key Account ManagerWorld Wide

Henning Stoppel

Sales EngineerGermany

Jens Berg

Sales EngineerGermany