Marketplace

-

kg-

mm-

€-

kg-

m/sRobots

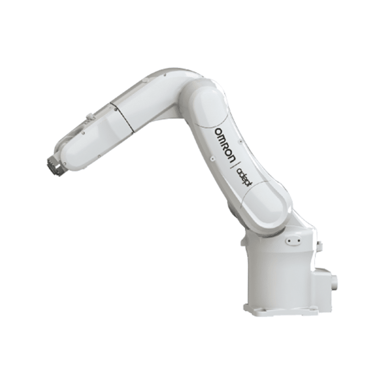

Robots enhance efficiency and precision across industries through seamless integration. Industrial robots drive high-volume production with speed and durability. Collaborative robots (cobots) enable safe, adaptable teamwork alongside humans in shared workspaces. Mobile robots, with smart navigation, streamline logistics by autonomously moving materials, uniting strength, safety, and mobility in modern automation.

Robots: Powering Industrial Automation

Robots are transforming industries by delivering precision, efficiency, and adaptability across a range of applications. Industrial robots drive high-speed manufacturing, handling repetitive tasks like welding and assembly with unmatched reliability. Collaborative robots, or cobots, work safely alongside humans, using advanced sensors to prevent collisions and enable flexible teamwork in shared workspaces. Mobile robots navigate autonomously to manage logistics, transporting materials in warehouses and factories with ease. By combining the strengths of industrial, collaborative, and mobile robots, businesses create integrated automation systems that streamline operations and boost productivity.

Benefits of Modern Robotics

Industrial robots bring speed and durability to large-scale production, making them essential for industries like automotive and electronics, where they reduce costs and improve output. Collaborative robots excel in environments requiring human-robot interaction, as their safety features and simple setup eliminate the need for extensive safety barriers, lowering integration costs. Mobile robots enhance efficiency by navigating complex spaces to deliver materials or transport finished goods, often working in tandem with stationary robots to ensure smooth workflows. This synergy allows mobile robots to supply components to industrial robots or move pallets prepared by cobots, optimizing the entire production process. Together, these robots reduce repetitive tasks, enabling workers to focus on creative and strategic roles, particularly in labor-scarce markets.

Programming and Integration Made Simple

Modern robots are designed for ease of use and seamless integration. Industrial robots rely on specialized programming to deliver precision in structured manufacturing environments. In contrast, cobots feature intuitive interfaces, such as drag-and-drop systems, allowing users with minimal coding skills to set them up quickly. Mobile robots use AI and mapping technologies to navigate autonomously, integrating effortlessly with warehouse or factory management systems. The ability of mobile robots to coordinate with stationary robots—delivering parts to assembly stations or transporting finished products—creates a cohesive automation ecosystem. Adding accessories like grippers or sensors further enhances robot versatility, adapting them to specific tasks across various industries.

Applications Driving Efficiency

Robots excel in a wide array of industrial applications. Industrial robots handle high-precision tasks like welding, cutting, and assembly in manufacturing plants, ensuring consistent quality. Collaborative robots take on repetitive or strenuous jobs, such as machine tending, packaging, or palletizing, working alongside humans to improve workplace efficiency. Mobile robots streamline logistics by autonomously transporting goods or components within warehouses and factories, often supporting stationary robots by supplying materials or moving finished products to storage. Beyond these, robots are used for quality inspection, screwdriving, and specialized tasks in confined spaces like laboratories. By automating routine operations, robots empower businesses to optimize their workforce, freeing employees for higher-value tasks in an era of labor shortages.

Find your automation solution now with our configurator