Marketplace

-

€AMR

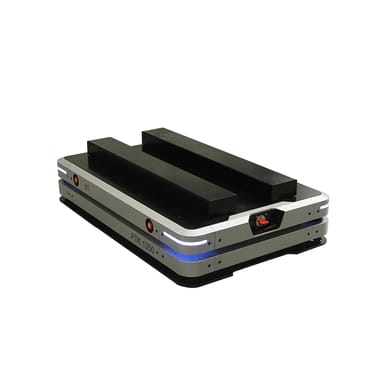

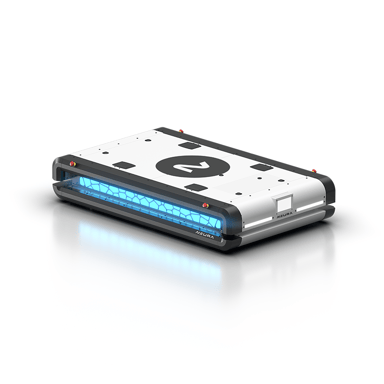

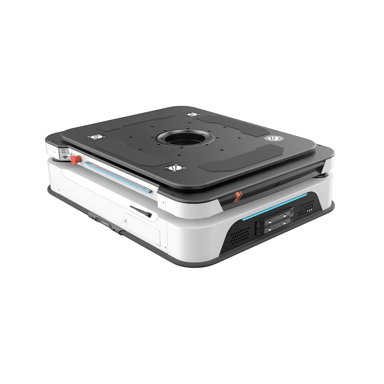

Autonomous Mobile Robots (AMRs) are intelligent, self-navigating machines that transport materials across warehouses and factories. Equipped with sensors and AI, they move safely and efficiently without fixed paths, adapting to dynamic environments to optimize logistics and productivity.

Autonomous Mobile Robots: Pioneering Flexible Automation

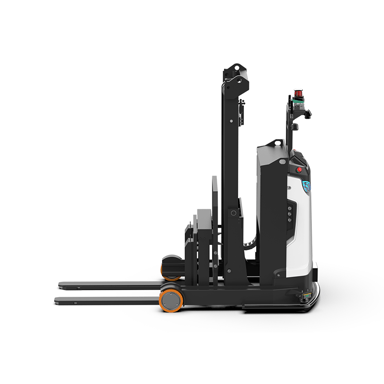

Autonomous Mobile Robots (AMRs) are reshaping logistics by navigating warehouses, factories, and other dynamic environments with intelligent independence. Unlike Automated Guided Vehicles (AGVs) that follow fixed paths, or industrial robots and cobots focused on stationary or human-assisted tasks, AMRs use advanced sensors, artificial intelligence, and real-time mapping to adapt to changing layouts, ensuring efficient material transport. Capable of handling payloads from tens to hundreds of kilograms, AMRs integrate seamlessly with warehouse systems, collaborating with stationary robots to streamline workflows. Their ability to autonomously navigate complex spaces makes them a cornerstone of modern automation, reducing manual labor and boosting productivity.

Advantages of AMRs

AMRs offer unparalleled flexibility, thriving in environments where layouts shift frequently, unlike the rigid infrastructure required by AGVs or industrial robots. Their AI-driven navigation allows them to avoid obstacles and reroute dynamically, making them ideal for fast-paced settings like e-commerce warehouses. Requiring minimal setup and no fixed tracks, AMRs lower installation costs and operate safely alongside workers without extensive safety barriers. Their energy-efficient designs and low maintenance needs enhance cost-effectiveness, enabling businesses to reassign workers from repetitive transport tasks to higher-value roles, particularly in labor-scarce markets.

Programming and Integration

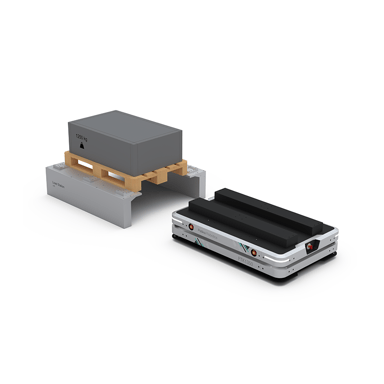

AMRs are designed for ease of use, featuring intuitive software that simplifies route planning and task assignment, even for users with minimal technical expertise. Their AI-powered systems enable real-time path adjustments, unlike the simpler programming of AGVs or the specialized coding often needed for industrial robots. AMRs integrate effortlessly with warehouse management systems (WMS) or factory networks, coordinating with cobots or industrial robots to deliver components or transport finished goods. Accessories like grippers or conveyors can be added to expand functionality, ensuring AMRs adapt to diverse automation needs with minimal effort.

Common Applications of AMRs

AMRs excel in logistics, handling tasks like inventory transport, order picking, and material delivery in warehouses and production floors. In e-commerce, they navigate aisles to retrieve items dynamically, while in manufacturing, they supply parts to assembly stations, complementing industrial robots or cobots. Their versatility extends to applications like hospital logistics, retail restocking, or even agriculture, where they move goods efficiently. By automating repetitive transport, AMRs help businesses optimize operations, scale efficiently, and address supply chain challenges in demanding industries.

Find your automation solution now with our configurator