Marketplace

-

kg-

mm-

€-

kg-

m/sCobot

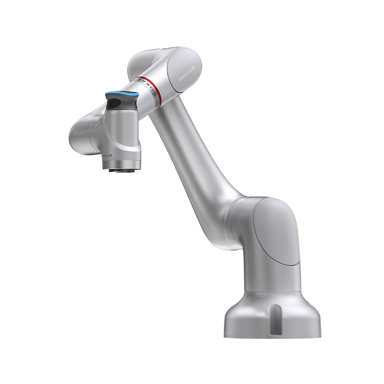

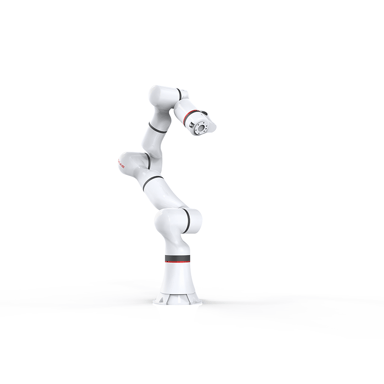

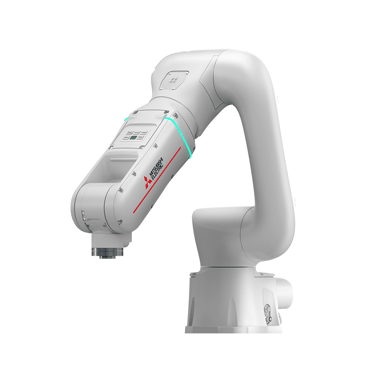

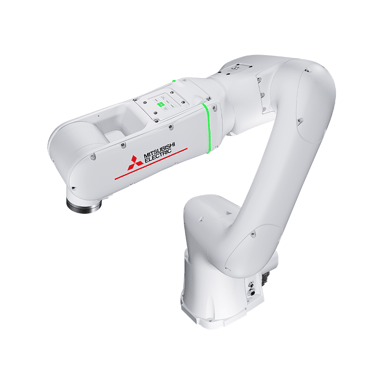

Collaborative robots, or cobots, combine easy programming with built‑in safety features for flexible automation. They can work safely alongside humans and handle tasks up to 30 kg, making them ideal for simple setup and fast integration across various applications.

Everything about Collaborative Robots (Cobots)

A collaborative robot, or cobot, is equipped with integrated sensors that detect collisions and safely stop movement. Cobots come with a range of safety features that enable efficient and collaborative automation. They are easy to operate, simple to integrate, and typically require less maintenance than traditional industrial robots. Most models have six joints for flexible motion and can be seamlessly integrated into existing production environments. With payloads between 25 kg and 30 kg—offered by manufacturers such as Doosan Robotics, Universal Robots, and Fanuc—they perform tasks like palletizing with precision and ease.

Advantages of Cobots

Compact and versatile, cobots can handle a wide variety of tasks. Compared to conventional industrial robots, they usually require fewer safety measures, helping reduce overall project complexity. Their small footprint makes them ideal for labs, research facilities, and other space‑limited environments. Brands like ABB provide specialized models for such collaborative workspaces. In logistics and manufacturing, cobots take over repetitive jobs—such as machine tending or pallet loading—relieving workers and allowing them to focus on more valuable tasks.

Programming and Integration

One of the biggest strengths of cobots is their user‑friendly programming. Many can be set up without advanced coding knowledge, often using intuitive drag‑and‑drop interfaces. Brands like Universal Robots also offer a wide range of plug‑ins and accessories, such as finger or vacuum grippers and tool attachments, making customization simple.

Common Applications

Thanks to their flexibility, cobots are suited for numerous applications—from machine tending and packaging to palletizing, screwdriving, welding, and quality inspection. By automating repetitive or physically demanding tasks, cobots help address labor shortages while ensuring employees can focus on more productive, engaging work.

Find your automation solution now with our configurator