Marketplace

-

kg-

mm-

€-

kg-

m/sIndustrial Robots

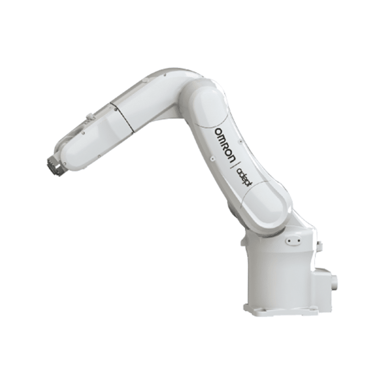

Industrial robots are built for precision, speed, and durability in structured production environments. Ideal for palletizing, welding, packaging, and assembly, they handle repetitive, heavy-duty tasks efficiently without direct human interaction. Their strength and reliability make them essential for large-scale automated manufacturing.

Industrial Robots: Powering High-Volume Manufacturing

Industrial robots are engineered for high-speed, high-precision tasks like welding, assembly, painting, and material handling in large-scale production environments. Unlike collaborative robots (cobots), which prioritize human-robot teamwork, industrial robots excel in structured settings, delivering unmatched efficiency and reliability for repetitive processes. With robust designs capable of handling heavy payloads, often exceeding 100 kg, industrial robots from manufacturers like FANUC or KUKA streamline demanding operations in industries such as automotive and electronics. Their ability to operate continuously with minimal downtime makes them a cornerstone of modern automation.

Advantages of Industrial Robots

Industrial robots offer significant benefits in high-volume manufacturing, where speed and accuracy are critical. They outperform cobots in tasks requiring power and precision, operating within controlled environments with safety barriers to maximize output. Their durability reduces maintenance needs, and their capacity to handle complex, repetitive tasks lowers production costs. Ideal for large-scale facilities, industrial robots enhance productivity by automating processes that demand consistency and strength.

Programming Industrial Robots

Programming industrial robots is tailored for precision, often requiring specialized software to manage complex tasks. While more technical than cobot programming, their systems ensure reliable performance in structured settings. Accessories like advanced grippers or welding tools, compatible with brands like YASKAWA, integrate seamlessly to meet specific manufacturing needs. This adaptability allows industrial robots to maintain high standards across diverse production lines.

Common Applications of Industrial Robots

Industrial robots are versatile, dominating tasks like welding, cutting, and assembly in manufacturing plants. They handle heavy-duty operations such as moving large components or palletizing bulky goods, which cobots typically cannot manage. Additional applications include precision painting and quality inspection in industries like aerospace or consumer goods. By automating repetitive, high-volume tasks, industrial robots free up resources, enabling businesses to optimize efficiency and focus on innovation in competitive markets.

Find your automation solution now with our configurator