Marketplace

0.58 kg

ROI Calculator

€2,200.00 - €2,600.00 excl. VAT.

From 300,00 € a month with lease buy or installment.

- Specifications

- Overview

- Description

- Downloads

- FAQ

- Similar products

due to the large and freely programmable jaw stroke with infinitely variable gripping force adjustment for flexible workpiece handling

Particularly suitable for the requirements of laboratory automation and electronics production due to the sealed design and smooth-running profile rail guidance system

by avoiding a workpiece loss thanks to integrated gripping force retention with loss detection

with constant gripping force over the entire length of the finger thanks to integrated spur gearing

Compatible with the leading manufacturers on the market thanks to a wide range of communication interfaces, as well as PLC function blocks and robot plug-ins

Featured on Unchained TV

Unfortunately, there are no use case videos yet for this product. Browse other robotics videos on Unchained TV.

| Overview | ||

|---|---|---|

| Weight | 0.58 kg | |

| Dimension | 83 x 62 x 78 mm | |

| Operating mode | Electric | |

| Performance | ||

|---|---|---|

| Min. Operating Temperature | 5 °C | |

| Max. Operating temperature | 55 °C | |

| Stroke | 53 mm | |

| Max. Gripforce | 50 N | |

| Closing time | 0.37 s | |

| Repeatability | 0.03 mm | |

| Interfaces | ||

|---|---|---|

| Supply voltage | 24 V | |

| Properties | ||

|---|---|---|

| IP classification | IP67 | |

The SCHUNK EGK 25 is an electric gripper for handling small workpieces. With 26.5mm stroke per jaw and a maximum gripping force of 50N, the gripper is versatile. With its weight of 0.58 kg, it can be perfectly used with collaborative robots.

Function

The highest level of functionality is available to you, thanks to the components embedded in the gripper. For example, the gripper fingers can be pre-positioned at high speed or for dipping in a workpiece carrier. The gripping force can be infinitely adjusted to the workpiece handling requirements. Workpiece recognition provides full process transparency for the user. In an emergency stop situation, workpiece loss can be avoided by the integrated gripping force retention.

BasicGrip and SoftGrip gripping modes are available. With BasicGrip and SoftGrip, continuous operation of the motor and thus permanent re-gripping of the workpiece is possible. With BasicGrip, the gripping speed is automatically optimized to the gripping force setting. With SoftGrip, fracture-sensitive workpieces can be gripped particularly gently by reducing the impulse forces to a minimum when they hit the workpiece.

Technical data

- Stroke per jaw: 26.5mm

- Min. gripping force: 20N

- Max. gripping force: 50N

- Weight: 0.58kg

Connectivity

A wide range of available communication interfaces simplifies dealing with the variety of control and robot manufacturers and ensures time savings during integration. Industrial Ethernet (PROFINET, EtherCAT, EtherNet/IP) enables direct integration without additional gateways into the control environment of leading PLC manufacturers on the market. With the Modbus RTU serial interface, the gripper can be connected to the tool flange of leading robot manufacturers without external cable routing. IO-Link is independent and offers flexibility in connecting to further networks.

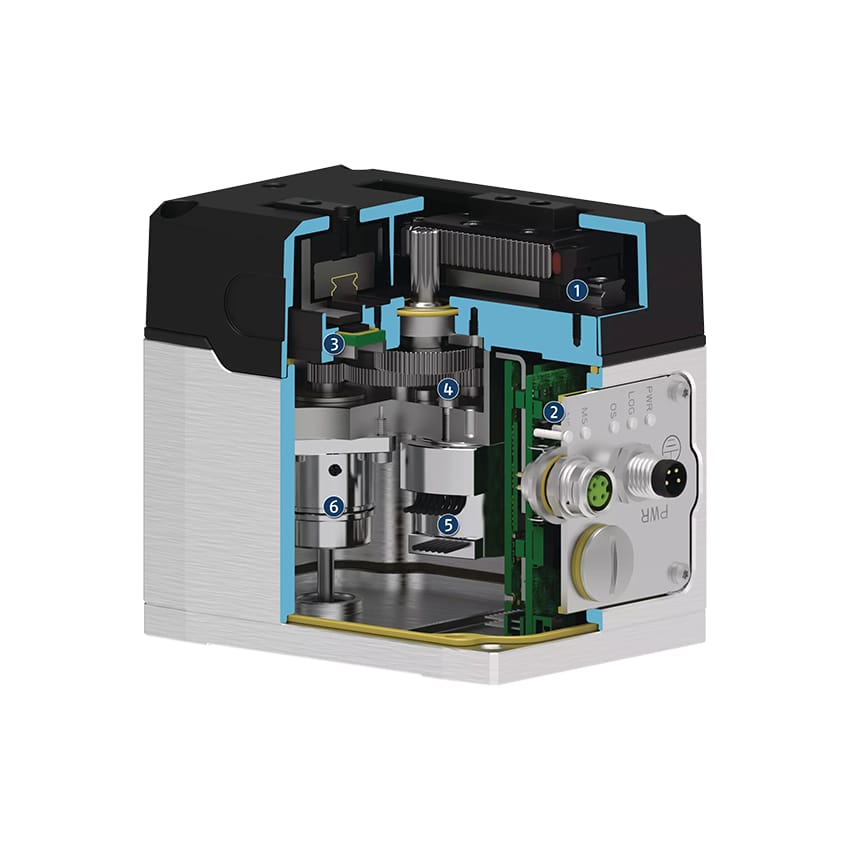

Functional cross-section

(last picture at the top of this page)

- Smooth-running profile rail guide with stainless steel face seal, food-grade lubrication and cover made of durable polycarbonate.

- Fully integrated and sealed control and power electronics with status LEDs and M8 connectors for connecting power supply and communication.

- High-resolution, output-side absolute encoder for precise positioning of the gripper jaws with permanent absolute position feedback.

- Sealed drive train with spur gear and pinion-rack principle for a constantly acting gripping force over the entire finger length, without minimum approach distance.

- Brushless motor for limited space and high torques thanks to externally mounted rotor.

- Electromagnetic brake with additional mechanism for maintaining gripping force and position during standstill or power failure.

To place an order, send us an inquiry through the button at the top of the page or contact us through the chat.

Unchained Robotics is the biggest marketplace for all things automation. We have over 36 brands with 9 different categories such as Cobots, Grippers, Cameras, Starter-kits, End-of-Arm-Accessories, Teaching-kits, Turnkey Solution, Cobot-Base and even

Services. For more information, check out our About page.

We have the answer for you in a series of blog post below:

Was du bei der Auswahl eines Cobots beachten solltest – The Specs that Matter

The Specs that Matter Die Top 10 Fragen zur Roboterwahl

Talk to an Automation expert

Have questions about this product, pricing, or your automation projects? Fill out the form and an automation expert from our team will be in touch within 24 hours.

Sebastian Hren

Key Account ManagerWorld Wide

Henning Stoppel

Sales EngineerGermany

Jens Berg

Sales EngineerGermany