Marketplace

-

€Feeding Systems

Feeding Systems automatically supply parts or materials to robotic cells and machines. They ensure continuous, efficient production by positioning and delivering components precisely for assembly, packaging, or inspection tasks.

What Are Feeding Systems?

Feeding Systems are automation components designed to deliver and position parts or materials in a consistent and controlled manner. They are essential in manufacturing and assembly processes, ensuring that each component arrives at the right place, at the right time, and in the correct orientation.

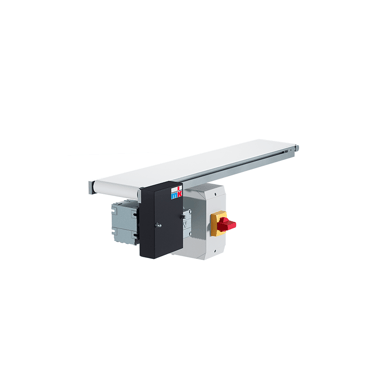

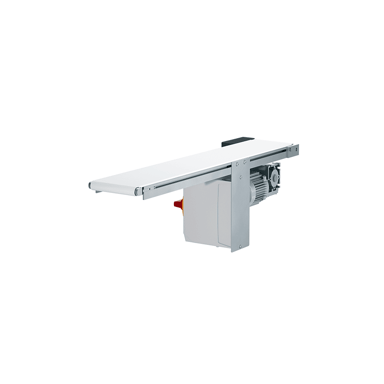

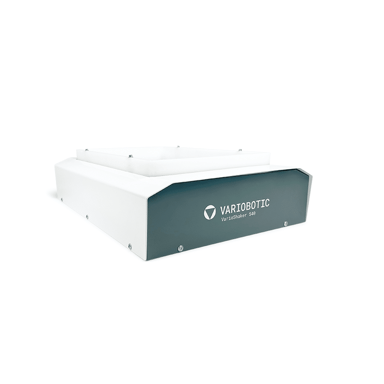

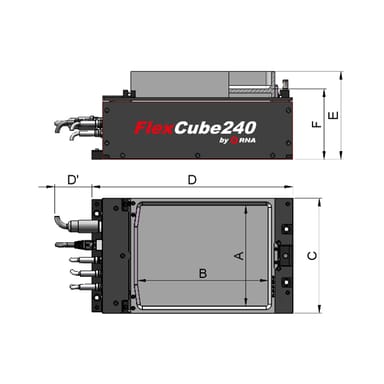

Common types include vibratory bowl feeders, conveyor systems, screw feeders, and flexible feeding units, which can handle a wide range of materials — from small mechanical parts to delicate electronic components.

Applications in Industry

Feeding systems are used across many industries, including automotive, electronics, packaging, medical technology, and consumer goods manufacturing. They provide reliable part handling in processes such as:

- Automated assembly lines

- Sorting and orientation of components

- Machine tending and robotic pick-and-place operations

- Packaging and labeling processes

By automating part delivery, these systems minimize manual intervention, increase output, and maintain consistent production quality.

Benefits of Using Feeding Systems

- Higher efficiency – Continuous supply of parts reduces idle time and increases throughput.

- Precision and repeatability – Accurate positioning ensures smooth downstream automation.

- Versatility – Supports various part types and sizes, from metal fasteners to plastic components.

- Reduced labor costs – Automation replaces repetitive manual feeding tasks.

- Improved safety – Minimizes worker exposure to repetitive or hazardous operations.

Whether using vibratory feeders for bulk materials or flexible feeding systems combined with vision sensors for variable parts, these solutions improve process reliability and speed.

Integration and Compatibility

Modern feeding systems are easily integrated into robotic cells and production lines, communicating with PLCs, vision systems, and robotic controllers. Manufacturers such as Asyril, FlexiBowl, and RNA Automation offer modular solutions compatible with leading robot brands like Universal Robots, FANUC, KUKA, and ABB.

Integration software and smart sensors allow real-time part detection, orientation, and flow control — supporting fully automated and adaptive material handling.

The Role of Feeding Systems in Automation

In modern smart factories, Feeding Systems are a crucial link between raw materials and robotic processes. They keep automation running smoothly, ensure precise material flow, and contribute to higher overall productivity. Whether for high-speed production or flexible batch manufacturing, feeding systems are essential for maintaining consistent, reliable, and efficient automation.

Find your automation solution now with our configurator