Marketplace

ROI Calculator

€17,153.00 excl. VAT.

From 1.000,00 € a month with lease buy or installment.

- Specifications

- Overview

- Description

- Downloads

- FAQ

- Similar products

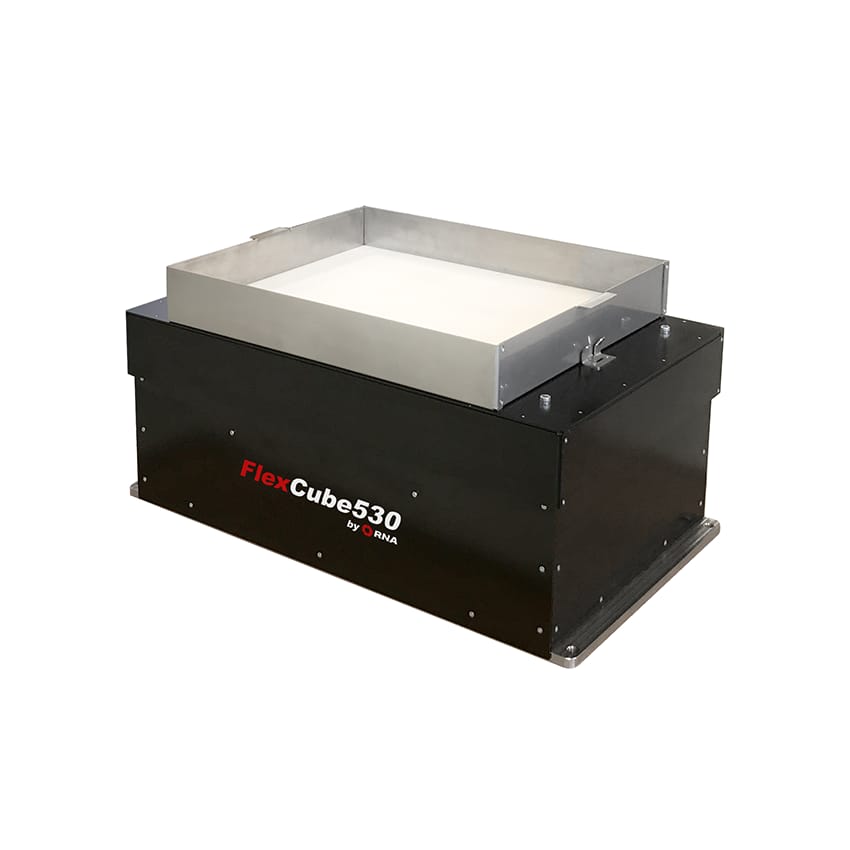

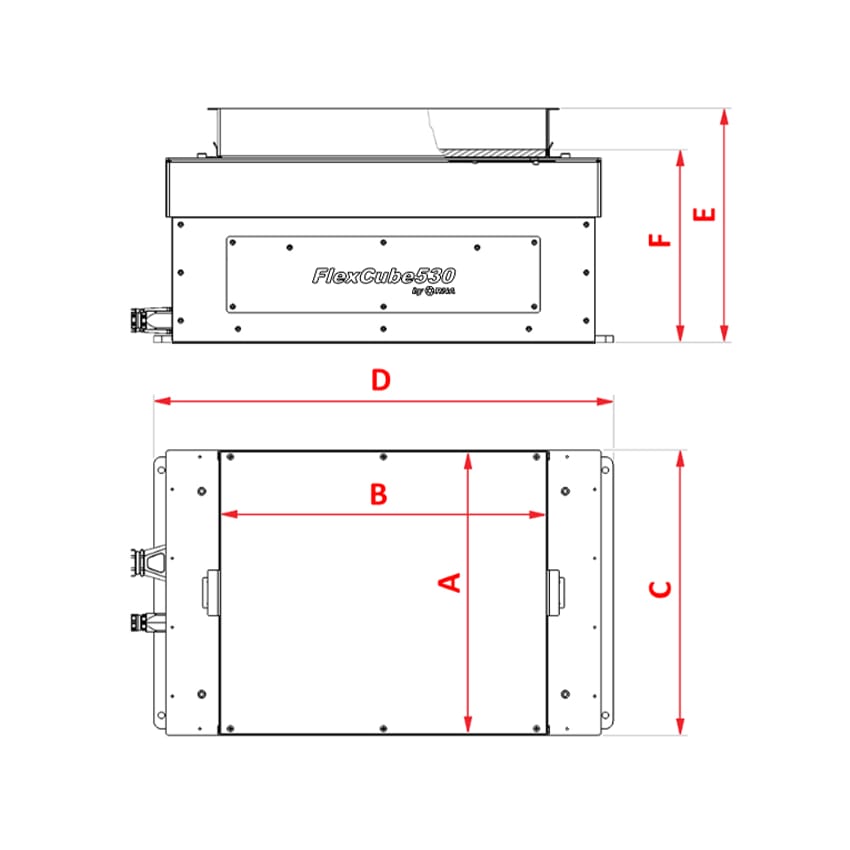

RNA FlexCube 530: 371 x 427 mm; ~560 mm platform diagonal

RNA FlexCube 530: 600 x 372 x 320 mm

RNA FlexCube 530 is ideal for parts from 30 to 150 mm in size for flat and cubic parts

Featured on Unchained TV

Unfortunately, there are no use case videos yet for this product. Browse other robotics videos on Unchained TV.

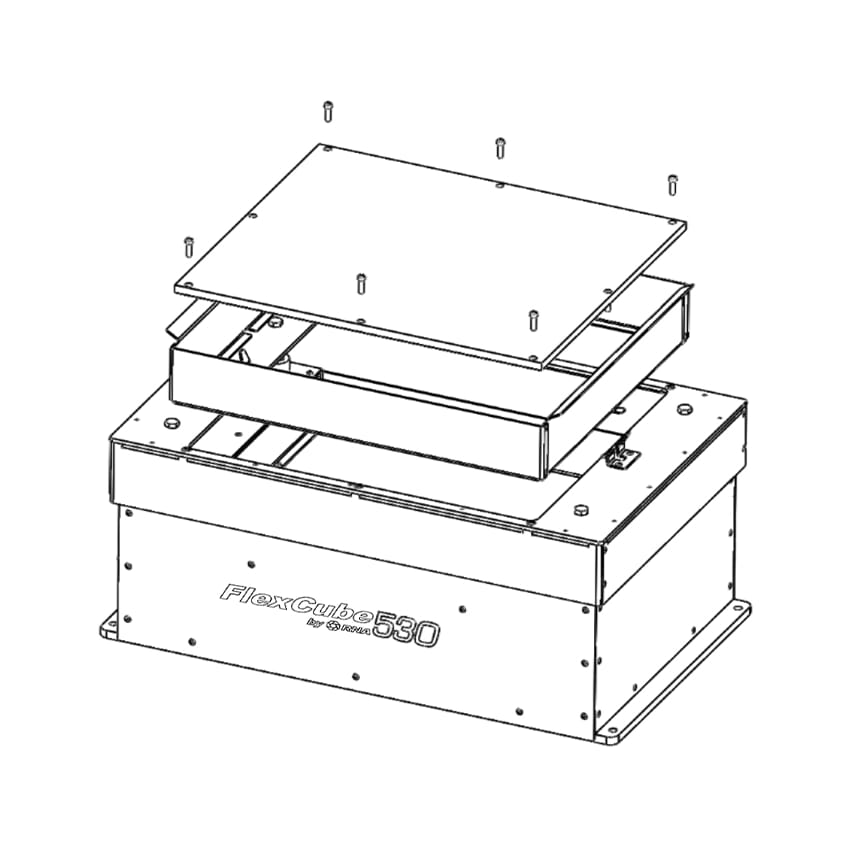

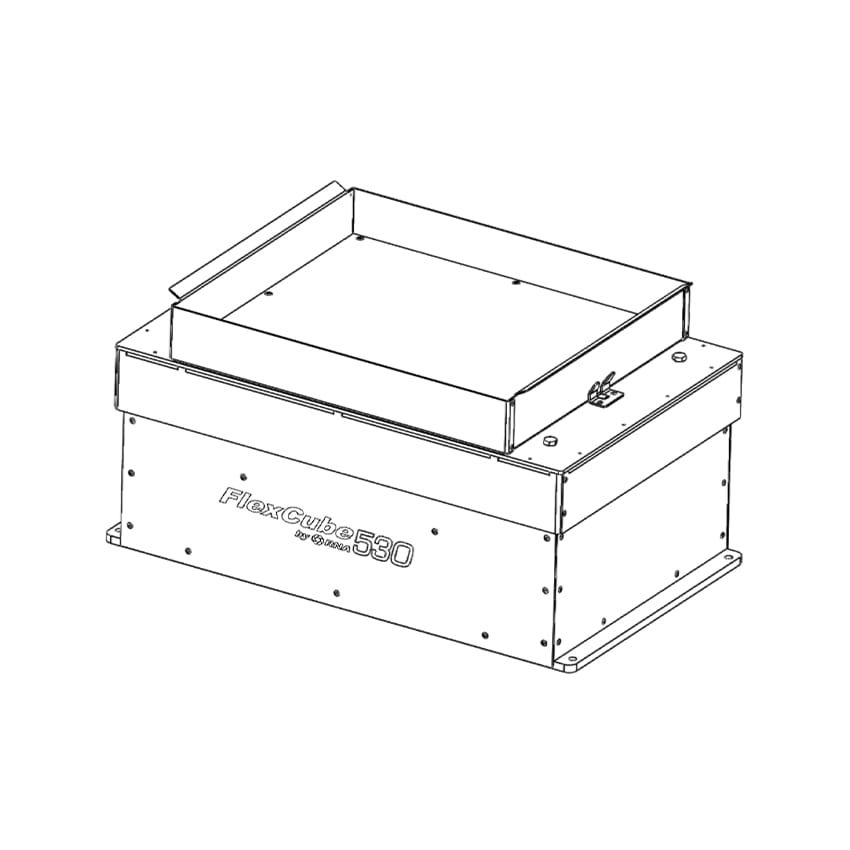

The Rhein-Nadel Automation RNA FlexCube product line can be specially adapted to the customer's tasks and requirements. 3 sizes (diagonal 240, 380, 530 mm) for parts with edge lengths from 0.1 mm to 100 mm and elongated parts up to 150 mm in length. Sizes 240, 380 and 530 are all available with the separate BVL-P Hopper, with proven vibration technology from RNA. The hoppers are adapted to the conveyed material (e.g. volume, coating, 3D bottom, antistatic, etc.) and offer optimal dispensing behavior. All sizes are available with integrated backlighting (red, blue, white, green, infrared, none) as well as optional front lighting.

Other benefits of RNA FlexCube vibratory platforms:

- Compatible with all part geometries: 99% of all parts of suitable size can be separated - including complex geometries and sensitive materials

- Shortest set-up and product changeover times for flexible, future-proof automation

- Extremely part-friendly separation: 3-axis vibration technology enables free movement of parts in all directions on the light table. Minimal abrasion as the parts are not recirculated as in the bowl feeder. Emptying of the platform possible.

- 3D vibration parameters adjustable from very fine to coarse, with extremely short reaction times (no start-up time), thus manipulation adapted to each material to be conveyed with the aim of the shortest possible cycle times.

- Virtually wear-free operation due to advanced solenoid coil actuators; no compressed air required

- No transmission of vibrations into surrounding machines due to decoupling of vibration platform and device base

- Precise part detection: integrated backlight / optional Eye+ part detection and vision system

- Systematic orientation and alignment of parts possible thanks to structured platforms (grooves, holes, recesses / nests)

- Easy installation and configuration through Feeder Control Center software

To place an order, send us an inquiry through the button at the top of the page or contact us through the chat.

Unchained Robotics is the biggest marketplace for all things automation. We have over 36 brands with 9 different categories such as Cobots, Grippers, Cameras, Starter-kits, End-of-Arm-Accessories, Teaching-kits, Turnkey Solution, Cobot-Base and even

Services. For more information, check out our About page.

We have the answer for you in a series of blog post below:

Was du bei der Auswahl eines Cobots beachten solltest – The Specs that Matter

The Specs that Matter Die Top 10 Fragen zur Roboterwahl

Talk to an Automation expert

Have questions about this product, pricing, or your automation projects? Fill out the form and an automation expert from our team will be in touch within 24 hours.

Sebastian Hren

Key Account ManagerWorld Wide

Henning Stoppel

Sales EngineerGermany

Jens Berg

Sales EngineerGermany