Marketplace

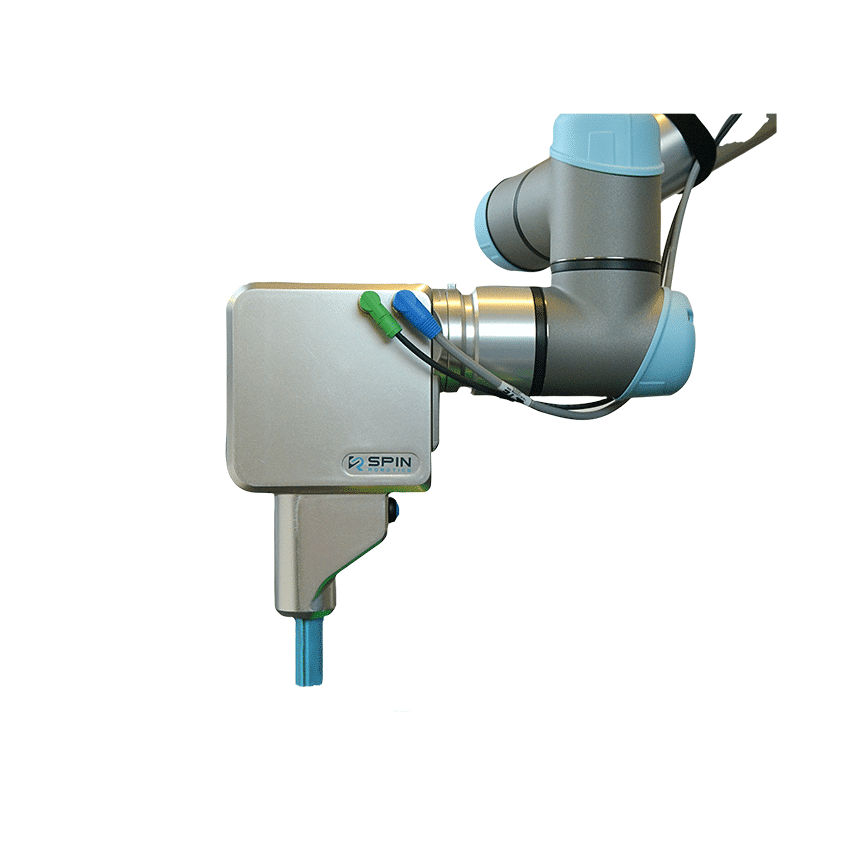

The SR35 is a brushless screwdriver system made for use with collaborative robots for safe, easy-to-use, and consistent screw assembly operation for screws requiring up to 3.5 Nm of tightening torque. The SR35 has several build-in features which enhances robot integration and supports collaborative work environments.

2.3 kg

ROI Calculator

€10,681.00 - €12,784.00 excl. VAT.

From 1.000,00 € a month with lease buy or installment.

- Specifications

- Overview

- Description

- Downloads

- FAQ

- Similar products

The automatic bit changer together with the tool allows you to work on multiple projects involving different screw types and sizes. Automate and save your time and money.

No experience with robots so far? Our tool is easy to set up, run and operate, all in 10 to 15 minutes.

SD35 features a safety shield and a built-in safety sensor (level-d performance) allowing it to safely work next to employees. Are you ready for a new collaborative colleague? Just plug it in!

Visualize and check your production quality on a screen. No more missing screw and returned batches!

Featured on Unchained TV

Automated bolting applications with the Spin Robotics SD35

Automated screwdriving at Danfoss with the Spin Robotics SD35 and a UR Cobot

| Overview | ||

|---|---|---|

| Weight | 2.3 kg | |

| Dimension | 325 x 54 x 159 mm | |

| Performance | ||

|---|---|---|

| Schraubengrößen Min | 2 mm | |

| Schraubengrößen Max | 5 mm | |

| Drehmoment Min | 0.8 | |

| Drehmoment Max | 3.5 | |

| Drehzahl Min | 0 | |

| Drehzahl Max | 750 | |

| Interfaces | ||

|---|---|---|

| Supply voltage | 48 V | |

| Nominal current | 8 A | |

| Communication | URCap Ethernet 24VIO | |

| Properties | ||

|---|---|---|

| IP classification | IP53 | |

| ESD sicher | Yes | |

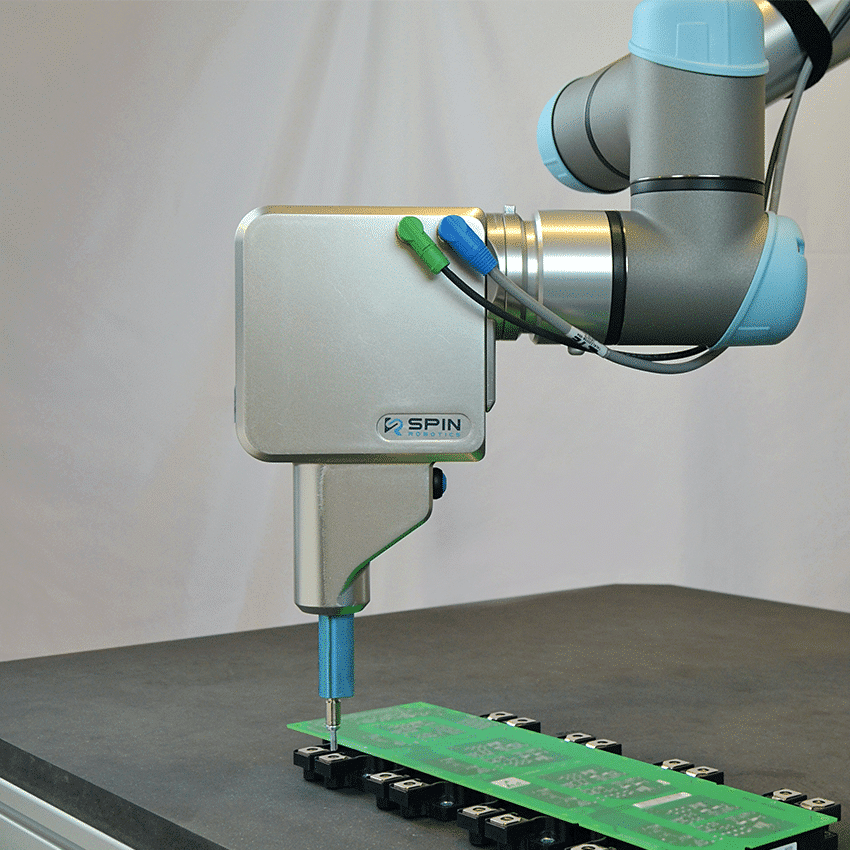

The Spin Robotics SD35 is made for pick & place screwdriving applications. This means that screws are picked up from an automatic screw feeder positioned within the reach of the robot.

SAFETY SHIELD

The safety shield covers the bit and screw when on the move, thereby protecting humans from rotating and sharp elements. If the tool hits an object, a safety sensor halts the robot. The built-in safety sensor is a performance level-d. making safe implementation easier.

EASY ROUTE PROGRAMMING

The supplied teach pen helps to pinpoint the exact position of the holes. When the free-drive button is pressed the tool can be moved to the next position. Use the configurable button to save waypoints.

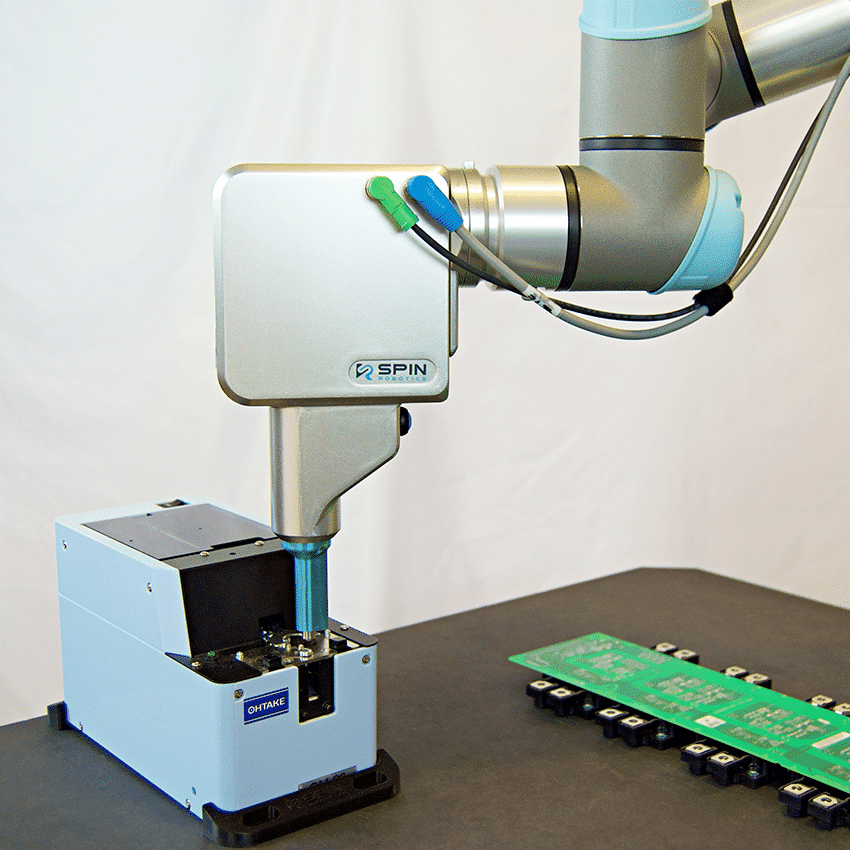

AUTOMATIC BIT CHANGE (OPTIONAL)

If multiple different screws are used at the same workstation, an optional bit changer can be acquired and used in combination with additional screw feeders.

SOCKETED SCREWS AND HARD TO REACH POSITIONS

Socketed screws can be inserted with up to 15 mm in depth measured from surface to top of the screw.

Variants

- Variant 1 - SD35 collaborative screwdriver. Includes: SD35 collaborative screwdriver, SpinBridge, SpinMount, Spin interface software

- Variant 2 - Complete Spin Package. Includes: SD35 collaborative screwdriver, SpinBridge, SpinMount, Spin Interface software, Automatic bit changing station, OM-26R screw feeder

To place an order, send us an inquiry through the button at the top of the page or contact us through the chat.

Unchained Robotics is the biggest marketplace for all things automation. We have over 36 brands with 9 different categories such as Cobots, Grippers, Cameras, Starter-kits, End-of-Arm-Accessories, Teaching-kits, Turnkey Solution, Cobot-Base and even

Services. For more information, check out our About page.

We have the answer for you in a series of blog post below:

Was du bei der Auswahl eines Cobots beachten solltest – The Specs that Matter

The Specs that Matter Die Top 10 Fragen zur Roboterwahl

Talk to an Automation expert

Have questions about this product, pricing, or your automation projects? Fill out the form and an automation expert from our team will be in touch within 24 hours.

Sebastian Hren

Key Account ManagerWorld Wide

Henning Stoppel

Sales EngineerGermany

Jens Berg

Sales EngineerGermany