Marketplace

-

€-

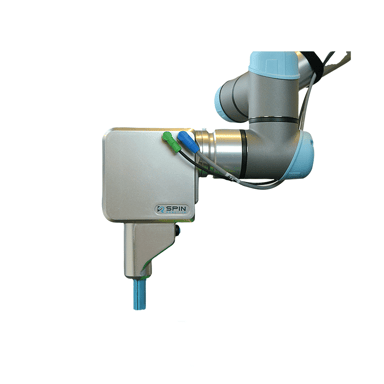

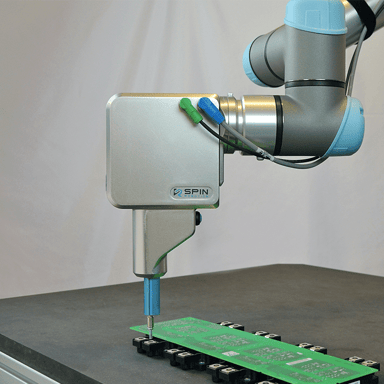

kgScrewdrivers

Robotic screwdrivers are specialized end-of-arm tools for automated screwdriving that deliver precise torque, consistent fastening quality, and shorter cycle times in assembly, electronics, and general industrial production.

What robotic screwdrivers are

Robotic screwdrivers are dedicated end-of-arm tools that automate the insertion and tightening of screws on industrial robots and cobots. They combine a drive unit, screw supply, and control electronics to achieve accurate torque, depth, and angle on every fastening cycle.

Technical characteristics

These tools typically offer configurable torque and speed profiles, screw presence detection, and OK/NOK feedback signals that can be logged for traceability. Many systems integrate directly with common robot brands via fieldbus, Ethernet, or digital I/O and can include automatic screw feeding, bit change, and error handling to minimize manual intervention and downtime.

Applications and benefits

Automated screwdriving is widely used on assembly lines for electronics, machinery, automotive subassemblies, and consumer products where repeatability and process stability are critical. By replacing manual fastening, manufacturers can increase throughput, reduce quality variations and stripping, and relieve operators from repetitive, ergonomically demanding screwing tasks in multi-shift operation.

Role in automation projects

Robotic screwdrivers are a key building block for flexible assembly cells and modular production lines. In combination with part feeding, positioning fixtures, and optionally vision systems, they enable scalable, fully traceable fastening processes that can be quickly adapted to new product variants and changing production volumes.

Find your automation solution now with our configurator