Marketplace

ROI Calculator

€11,175.00 excl. VAT.

From 1.000,00 € a month with lease buy or installment.

- Specifications

- Overview

- Description

- Downloads

- FAQ

- Similar products

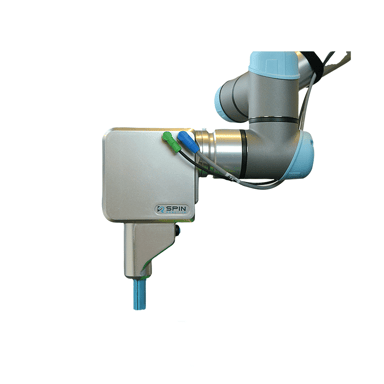

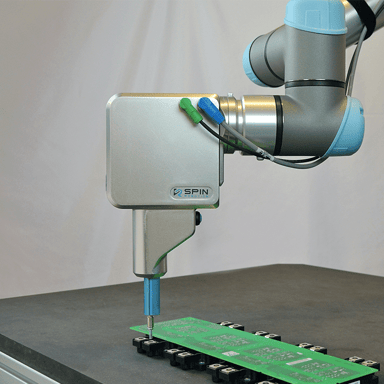

As an extension for existing machines, robots can be easily upgraded with the CLAMPBOOSTER system. A complicated, cost-intensive retrofit of the machine is not necessary. Direct installation is possible for newly planned machining centers.

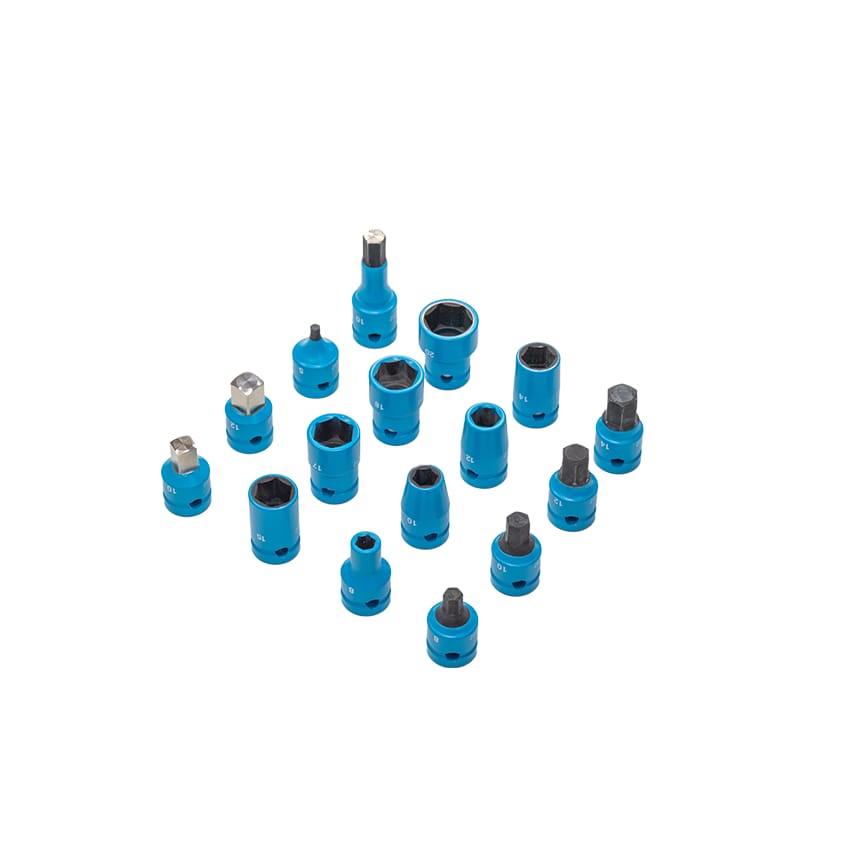

Thanks to interchangeable adapters, the CLAMPBOOSTER is compatible with almost all vise systems available on the market. The existing production process remains untouched and can be continued as usual. CNC production centers that have been fully automated thanks to CLAMBPOOSTER can operate around with clock without manual intervention.

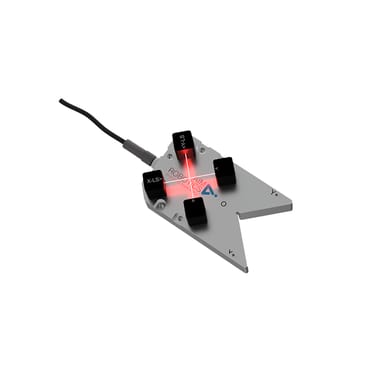

With CLAMPBOOSTER, the opening travel of the vise can be precisely adjusted by programming the spindle revolutions. The required torque can be adjusted flexibly and without programming knowledge via the system's graphical software.

Made in Bavaria, Germany. The CLAMPBOOSTER is manufactured in Bavaria to the highest quality standards. Form and function deliberately go hand in hand. The high quality standards of CNC production, automated down to the last detail, are reflected in the ultra-modern and appealing design.

Featured on Unchained TV

Unfortunately, there are no use case videos yet for this product. Browse other robotics videos on Unchained TV.

Perfection in automation. The drive for your manual vise.

Why make a manufacturing process unnecessarily complex by performing a complicated and expensive CNC machine vise system replacement? Why take a risk with CNC automation when well-rehearsed manpower and existing manual vise systems work efficiently? And drive an already high investment for retrofitting the existing machine or for the new acquisition of a CNC machining center even higher?

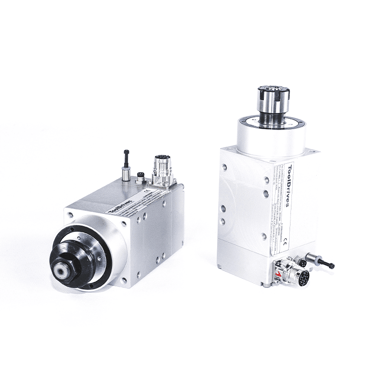

Don't underestimate the power a small electric spindle drive can have on a large CNC machine. The CLAMPBOOSTER makes it so easy: You still use your existing vise systems. You maintain an efficient manufacturing process. You do not have to retrain your employees. You keep your costs under control with maximum flexibility. You carry on almost as before - and solve the problem of automation quite simply with the CLAMPBOOSTER system! On both exising and new CNC machines.

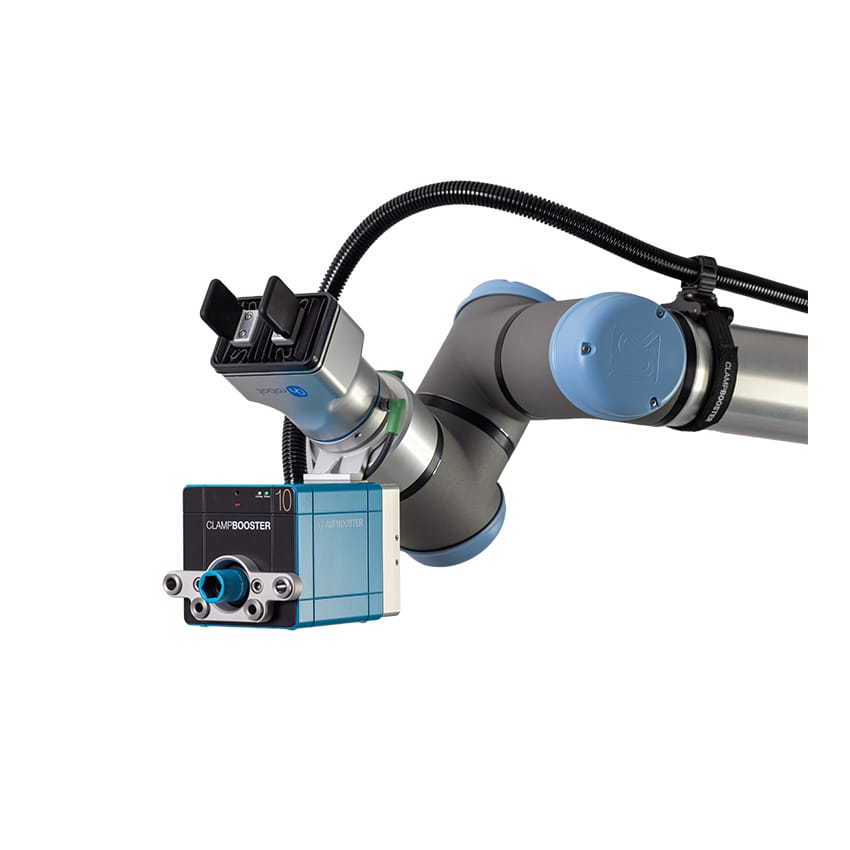

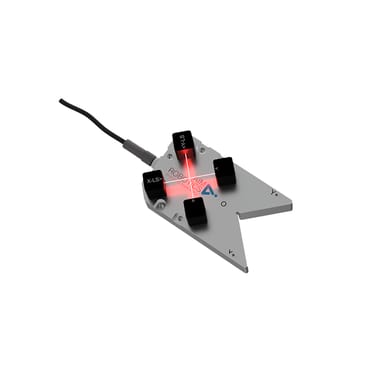

The CLAMPBOOSTER is attached to the robot arm, guided directly to the vise and closes it according to the defined tightening torque. After the material has been processed in the machine, the CLAMPBOOSTER opens the vise, the workpiece is unloaded and the production process restarts.

Without any additional training effort and without any changes in the usual clamping process, the CLAMPBOOSTER can be implemented in just a few minutes. Continue to use your trusted vise systems, your familiar working environment and your reliably functioning production process! Without reprogramming existing production data to new vises, you do not even have to introduce new quality assurance processes.

Additional technical details

- Dimensions (LxWxH): 120 x 100 x 100 mm

- Weight: 1.95 kg

- Power supply: 100 - 240V AC, 6-2,5 A

- Compressed air supply: 5 - 6,5 bar

- Flexible and individually controlled torque: 5-100 Nm

- Very short closing and opening time: approx. 5 seconds

- Blow-off nozzle: integrated

- Software updates: online

- Remote maintenance: integrated

- Mechanics: maintenance-free

Download the CLAMPBOOSTER Brochure (DE) here!

Download the CLAMPBOOSTER Product Flyer (EN) here!

Download the CLAMPBOOSTER STEP File here!<br>

To place an order, send us an inquiry through the button at the top of the page or contact us through the chat.

Unchained Robotics is the biggest marketplace for all things automation. We have over 36 brands with 9 different categories such as Cobots, Grippers, Cameras, Starter-kits, End-of-Arm-Accessories, Teaching-kits, Turnkey Solution, Cobot-Base and even

Services. For more information, check out our About page.

We have the answer for you in a series of blog post below:

Was du bei der Auswahl eines Cobots beachten solltest – The Specs that Matter

The Specs that Matter Die Top 10 Fragen zur Roboterwahl

Talk to an Automation expert

Have questions about this product, pricing, or your automation projects? Fill out the form and an automation expert from our team will be in touch within 24 hours.

Sebastian Hren

Key Account ManagerWorld Wide

Henning Stoppel

Sales EngineerGermany

Jens Berg

Sales EngineerGermany