Marketplace

-

€Automation Control Systems

Automation Control Systems form the core of modern robotic and industrial processes. They manage communication, motion, and safety functions — ensuring smooth coordination between robots, sensors, and production equipment for reliable and efficient operation.

What Are Automation Control Systems?

Automation Control Systems are the central units that monitor, coordinate, and regulate all functions in robotic and industrial automation setups. They process data from sensors and input devices, send commands to actuators and motors, and ensure that every step of a process runs in precise sequence.

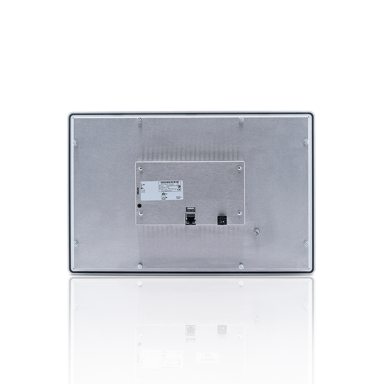

Typical components include robot controllers, PLCs (Programmable Logic Controllers), motion controllers, HMIs (Human-Machine Interfaces), and various communication modules. Together, they provide the intelligence and structure behind every automated operation.

Applications in Robotics and Industry

Automation control systems are used in nearly all industrial and collaborative robotics environments, including:

- Assembly and production lines – coordinating robots, conveyors, and sensors

- Machine tending and CNC automation – synchronizing machine cycles and tool movements

- Packaging and logistics – ensuring timing and accuracy in high-speed systems

- Quality control and testing – collecting and processing sensor data in real time

Whether managing a single robot cell or a fully networked smart factory, control systems ensure accuracy, repeatability, and safety at every level.

Benefits of Automation Control Systems

- Precise process coordination – Synchronizes robots, sensors, and actuators in real time

- Scalable performance – Easily expandable for future system growth or new tasks

- User-friendly operation – HMIs and intuitive interfaces simplify setup and diagnostics

- Increased efficiency – Optimized workflows reduce downtime and energy consumption

- High safety standards – Integrated monitoring and emergency controls protect users and machines

With these benefits, control systems form the backbone of modern industrial automation — combining performance, flexibility, and reliability in one solution.

Integration and Compatibility

Modern control systems are designed for seamless integration with both industrial and collaborative robots. They support standard communication protocols such as EtherCAT, Modbus, PROFINET, and IO-Link, ensuring compatibility across different hardware and software platforms.

Many manufacturers offer powerful control solutions that integrate directly with leading robot brands such as Universal Robots, KUKA, and FANUC. Modular architectures and open interfaces make it easy to connect additional sensors, actuators, and visualization systems.

The Role of Automation Control Systems in Modern Production

In the era of Industry 4.0, automation control systems are more important than ever. They enable data-driven production, predictive maintenance, and real-time process optimization. By connecting machines, robots, and software into one intelligent network, these systems make factories smarter, faster, and more efficient.

Whether for small cobot workcells or fully automated industrial lines, Automation Control Systems ensure the precision and reliability that modern production demands.

Find your automation solution now with our configurator