Marketplace

ROI Calculator

€79,700.00 excl. VAT.

From 1.000,00 € a month with lease buy or installment.

- Specifications

- Overview

- Description

- Downloads

- FAQ

- Similar products

Featured on Unchained TV

Unfortunately, there are no use case videos yet for this product. Browse other robotics videos on Unchained TV.

With the mkf LiFo Storage System, you get a standalone solution for the flexible storage of parts for your assembly line, packaging, or processing machine. For example, during the night shift, you can expand your capacities or compensate for staff shortages.

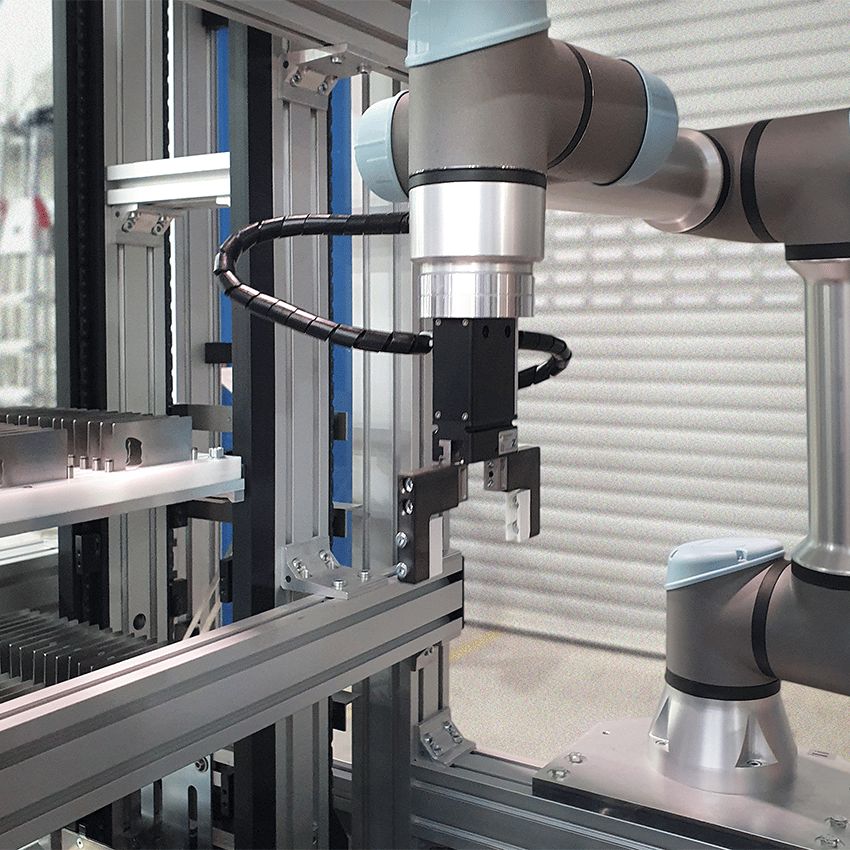

The integrated cobot (collaborative robot) UR5e from Universal Robots can take over various handling tasks after convenient adjustment of the parameters. The LiFo Storage System handles the loading and unloading of your equipment, component testing, various measuring tasks, or several assembly steps. With its convenient transport option, the LiFo storage system can be used flexibly in your production.

Workpieces are picked up in the task-specific modified workpiece carrier (in the standard version with a pick-up area of 250 x 400 mm and a max. total weight of 40 kg/WT).

The LiFo Storage System has an OPC UA interface.

The mkf LiFo Storage System consists of three main assemblies:

1. Frame made of mk-aluminum profile system .

- To hold the storage and conveyor combination, the cobot, and the electrical installation

- Openings are closed with transparent polycarbonate panes

- Safety-monitored flaps for convenient loading and unloading

- Maintenance door on the backside

- Dimensions (L x W x H): approx. 1500 x 1500 x 2400 mm

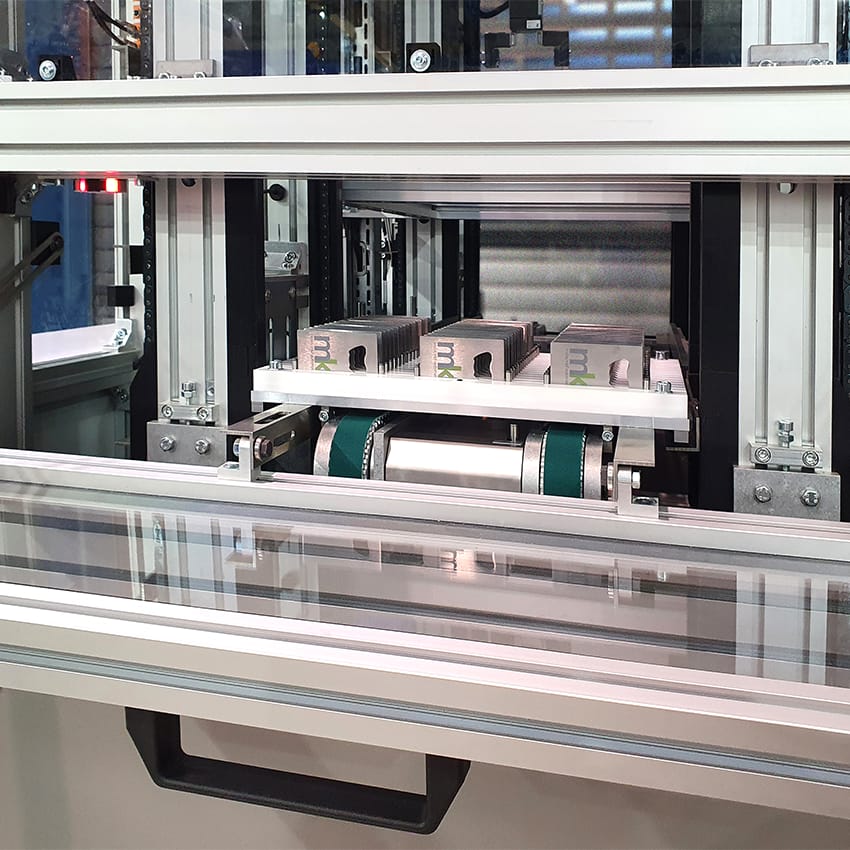

2. Storage and conveying combination

- Consisting of 2 double-strand chain conveyors and one toothed belt conveyor

- The chain conveyors store the workpiece carriers

- Toothed belt conveyor for transporting the workpiece carriers to the working position of the cobot

3. Universal Robots UR5e

- Collaborating robot

- 6-axis, movement radius 850 mm

- Payload 5 kg

- Integration into Universal's Polyscope software environment using URCap mkf LiFo memory

- Control via UR5e operator panel

- Integrated recipe management

- Easy editing of parameters through user-oriented GUI

To ensure flexibility, workpiece carrier holders are used in the LiFo Storage System, which are provided with component-specific workpiece nests. Please note that all parts in contact with the workpiece (for example, gripper finger, workpiece carrier attachment) are not included in the scope of delivery.

Start to finish in 4 steps:

- Placement of the LiFo Storage System at the place of use (e.g., in front of an assembly plant)

- Selecting or creating the appropriate recipe

- Check properties

- Starting the automatic mode of the LiFo Storage System

To place an order, send us an inquiry through the button at the top of the page or contact us through the chat.

Unchained Robotics is the biggest marketplace for all things automation. We have over 36 brands with 9 different categories such as Cobots, Grippers, Cameras, Starter-kits, End-of-Arm-Accessories, Teaching-kits, Turnkey Solution, Cobot-Base and even

Services. For more information, check out our About page.

We have the answer for you in a series of blog post below:

Was du bei der Auswahl eines Cobots beachten solltest – The Specs that Matter

The Specs that Matter Die Top 10 Fragen zur Roboterwahl

Talk to an Automation expert

Have questions about this product, pricing, or your automation projects? Fill out the form and an automation expert from our team will be in touch within 24 hours.

Sebastian Hren

Key Account ManagerWorld Wide

Henning Stoppel

Sales EngineerGermany

Jens Berg

Sales EngineerGermany