Marketplace

-

€Automation Software

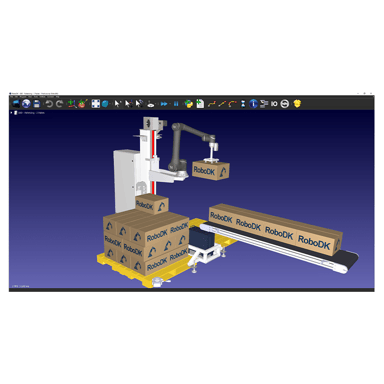

Automation Software connects and controls robots, machines, and sensors within industrial systems. It enables programming, monitoring, and optimization of automated processes — improving productivity, flexibility, and ease of use across all areas of modern manufacturing.

What Is Automation Software?

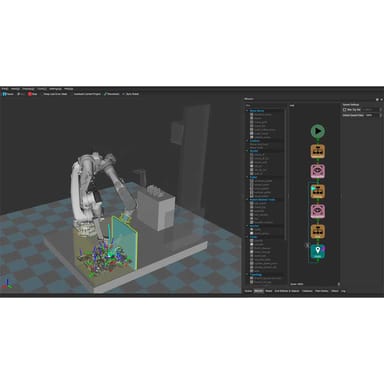

Automation Software is the digital foundation of modern industrial and robotic systems. It manages communication between devices, coordinates workflows, and provides the user interface for programming and monitoring automation processes. From robot control and motion planning to data collection and process visualization, automation software ensures that every step in production runs efficiently and reliably.

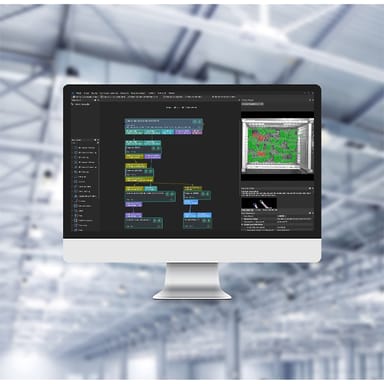

Modern platforms integrate robot control, PLC programming, HMI design, and analytics in one environment, supporting everything from small collaborative robot cells to complex multi-machine systems.

Applications in Robotics and Industry

Automation software is used in nearly every industrial and manufacturing sector, including:

- Robot programming and control – simplifying setup and path planning

- Machine coordination – synchronizing robotic cells and production equipment

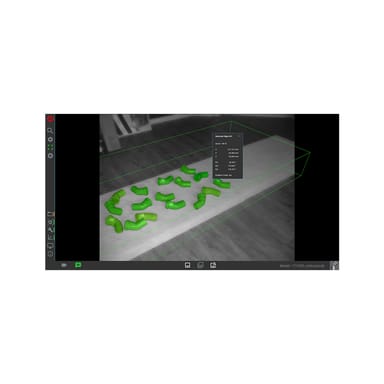

- Process monitoring – visualizing performance data and system status in real time

- Predictive maintenance – analyzing operational data to reduce downtime

- Quality assurance – integrating inspection and measurement tools into workflows

With intuitive interfaces and no-code or low-code environments, automation software allows operators to adjust and optimize processes without advanced programming knowledge.

Benefits of Automation Software

- Improved efficiency – Optimizes cycle times, resource use, and throughput

- Flexibility – Easily adapts to new products or production changes

- Data-driven insights – Collects and analyzes information for smarter decision-making

- Simplified programming – Reduces setup time with user-friendly tools and templates

- Seamless connectivity – Integrates robots, PLCs, sensors, and external databases in one platform

By centralizing control and monitoring, automation software enables manufacturers to create intelligent, connected, and highly efficient production systems.

Integration and Compatibility

Modern automation software supports a wide range of communication protocols such as EtherCAT, PROFINET, Modbus, and OPC UA, ensuring smooth integration across different hardware brands and devices.

It is compatible with leading robots and control systems from Universal Robots, KUKA, FANUC, ABB, Siemens, and Beckhoff, providing flexibility in both new and existing setups. Many software platforms also connect to cloud services or MES/ERP systems, enabling real-time data sharing and remote system management.

Manufacturers like OnRobot, Siemens, Omron, and Mitsubishi Electric offer scalable solutions tailored to applications ranging from small workcells to full smart factories.

The Role of Automation Software in Smart Manufacturing

In the era of Industry 4.0, Automation Software serves as the link between machines, people, and data. It transforms traditional automation into a networked, intelligent system capable of self-optimization and adaptive control. Whether for robot programming, process visualization, or data analytics, the right software ensures that automation is not only powerful but also accessible and transparent.

By combining usability, connectivity, and intelligence, automation software helps companies achieve greater efficiency, flexibility, and long-term competitiveness in modern production environments.

Find your automation solution now with our configurator