Marketplace

-

€Simulation Software

Simulation Software enables engineers to virtually design, test, and refine robotic and industrial processes before they go live. It helps cut setup time, reduce risks, and ensure faster, more reliable automation deployment.

What Is Simulation Software?

Simulation Software is a powerful tool used in robotics and industrial automation to model and visualize systems in a virtual environment. It enables users to create digital twins of robots, machines, and production lines to test performance, detect issues, and optimize workflows before real-world deployment.

By simulating automation processes, engineers can verify robot reach, collision avoidance, cycle times, and tool paths — ensuring a smooth transition from design to production. This approach saves time, reduces costs, and supports continuous improvement in manufacturing efficiency.

Applications in Robotics and Automation

Simulation software is used across a wide range of industries and automation tasks, including:

- Robot programming and motion planning – testing toolpaths, sequences, and timing

- Production line design – optimizing layout, flow, and process coordination

- Feasibility studies – verifying reachability and cycle time before equipment purchase

- Operator training – providing a safe environment for learning and experimentation

- Digital twin development – linking virtual models with live data for predictive control

By enabling accurate, virtual testing, simulation tools reduce the need for physical prototypes and accelerate the commissioning of automation systems.

Benefits of Simulation Software

- Reduced setup time – Plan and validate systems before installation

- Cost savings – Avoid errors and unnecessary equipment changes

- Improved safety – Test complex operations in a virtual environment

- Higher accuracy – Optimize motion, layout, and resource allocation with precision

- Faster commissioning – Seamlessly transfer virtual results to real robot programs

These benefits make simulation software essential for efficient, low-risk automation design — especially in complex or high-precision applications.

Integration and Compatibility

Modern simulation platforms integrate directly with robot controllers, PLCs, and automation software, allowing users to import real robot models and programming data. They are compatible with major robot brands such as Universal Robots, KUKA, FANUC, ABB, and Yaskawa, ensuring realistic kinematic and behavioral modeling.

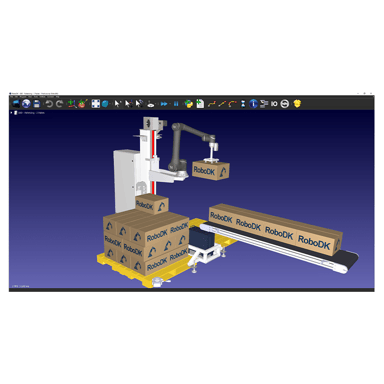

Manufacturers like RoboDK, Siemens Tecnomatix, and Visual Components offer scalable solutions that support 3D visualization, CAD integration, and digital twin synchronization. This makes it possible to connect virtual simulations with live production data for continuous optimization and predictive maintenance.

The Role of Simulation Software in Modern Automation

In modern smart factories, Simulation Software bridges the gap between design and operation. It enables data-driven engineering, reduces commissioning times, and supports flexible production planning — key advantages in an increasingly dynamic manufacturing landscape.

Whether used for robot path planning, layout optimization, or digital twin development, simulation software provides the insight and confidence needed to deploy automation systems efficiently and successfully.

Find your automation solution now with our configurator