Marketplace

Introducing MalocherBot

Effective automation for projects big and small.

Effective automation for projects big and small.

Success Stories

MalocherBot

Modular. Turnkey. Affordable.

Master your manufacturing with MalocherBot. Powered by LUNA OS

MalocherBot is modular automation designed with one thing im mind: your ROI.

Powered by the LUNA Automation Operating System, MalocherBot offers a complete system for commonly automated processes.

Setup in < 1 day. No coding. Just automation.

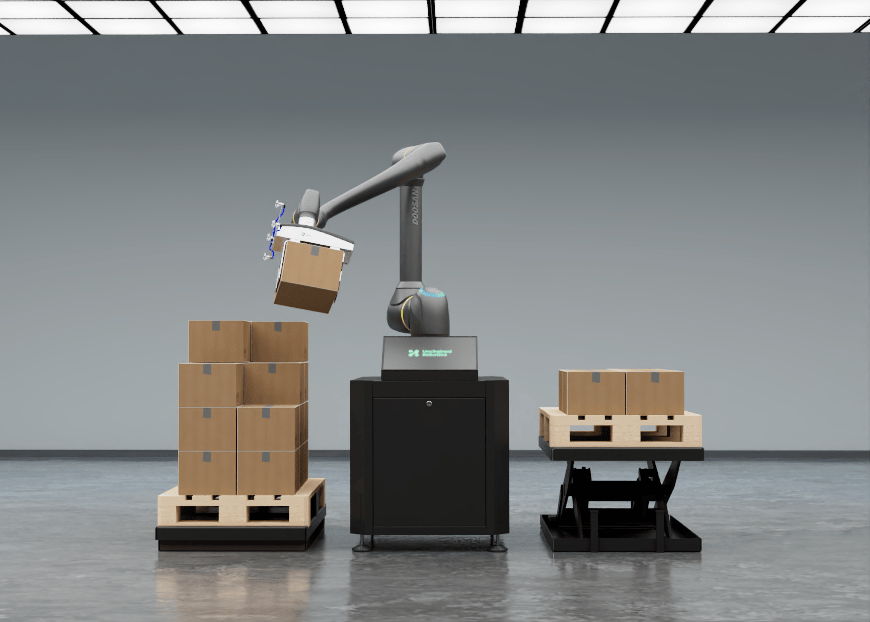

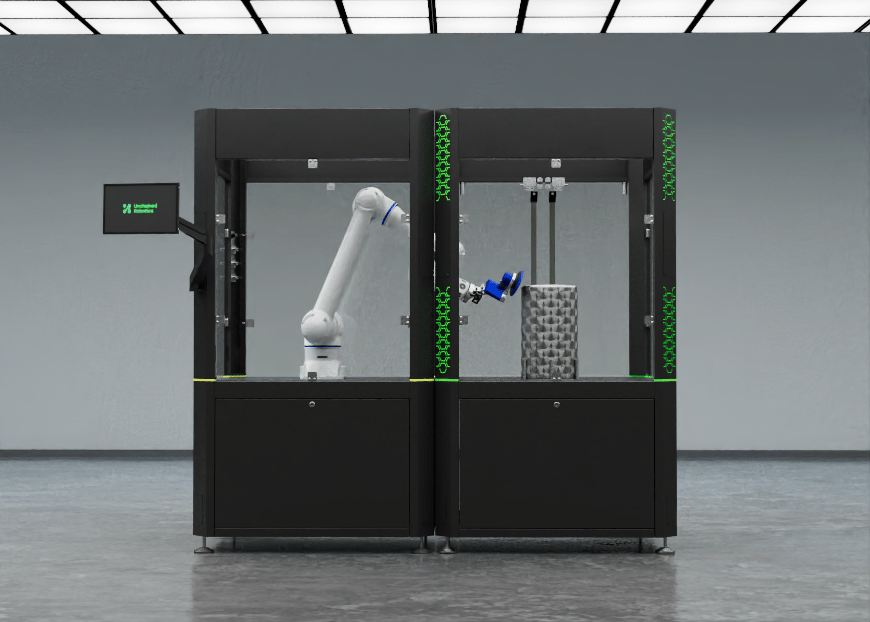

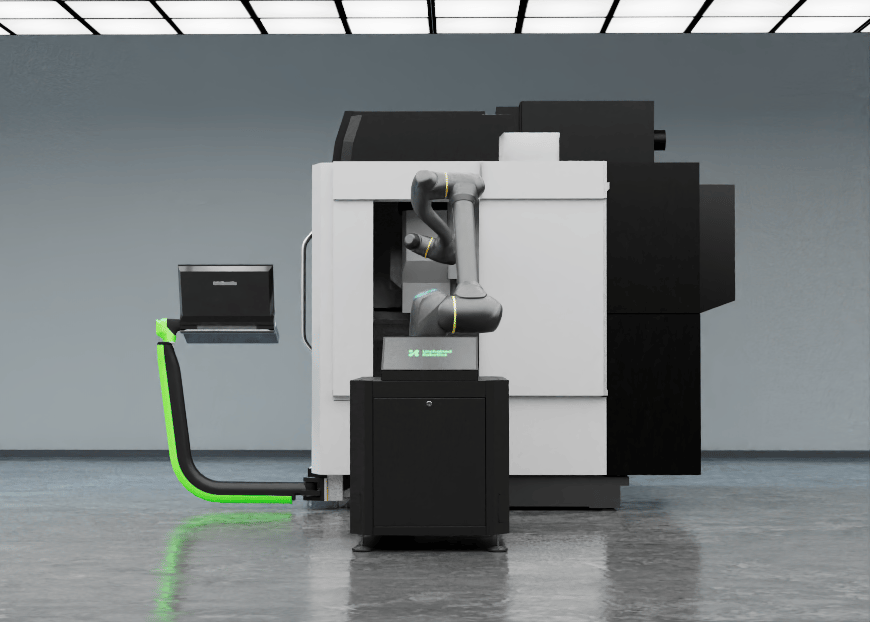

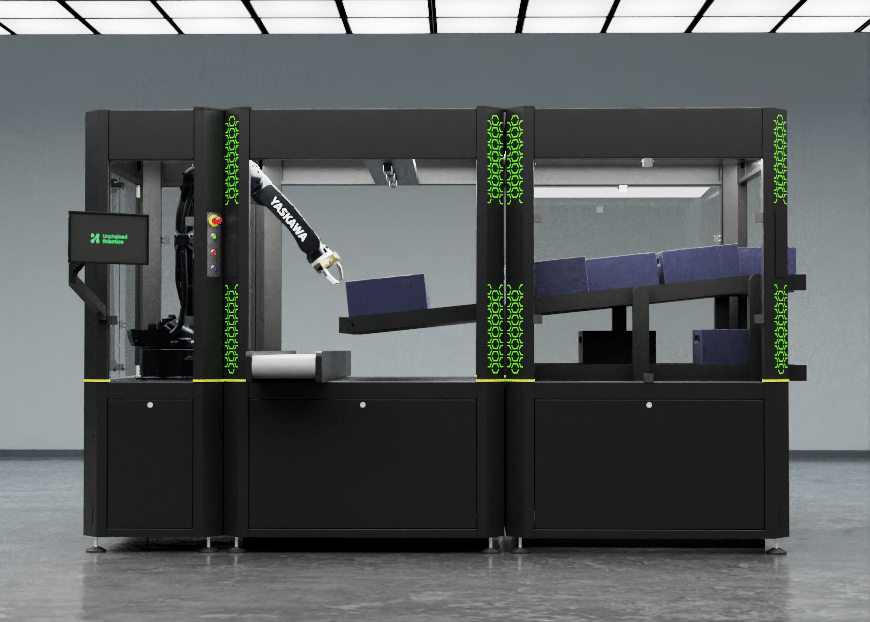

MalocherBot Models

From Palletizing to Bin Picking, MalocherBot is a master of manufacturing.

Discover MalocherBot models below.