Marketplace

Make sure your processes are up to date before you expand them. To avoid potential malfunctions and other problems, mkf GmbH offers expert online consulting to help you perform an initial analysis and identify weaknesses in your proposed solutions. The experts at mkf GmbH are proficient in VDA 19/2, so you don’t have to.

ROI Calculator

€390.00 - €790.00 excl. VAT.

From 100,00 € a month with lease buy or installment.

- Overview

- Description

- Downloads

- FAQ

- Similar products

- Online

- On-site

- Analysis of the requirements for product cleanliness

- Analysis of environmental conditions and process steps

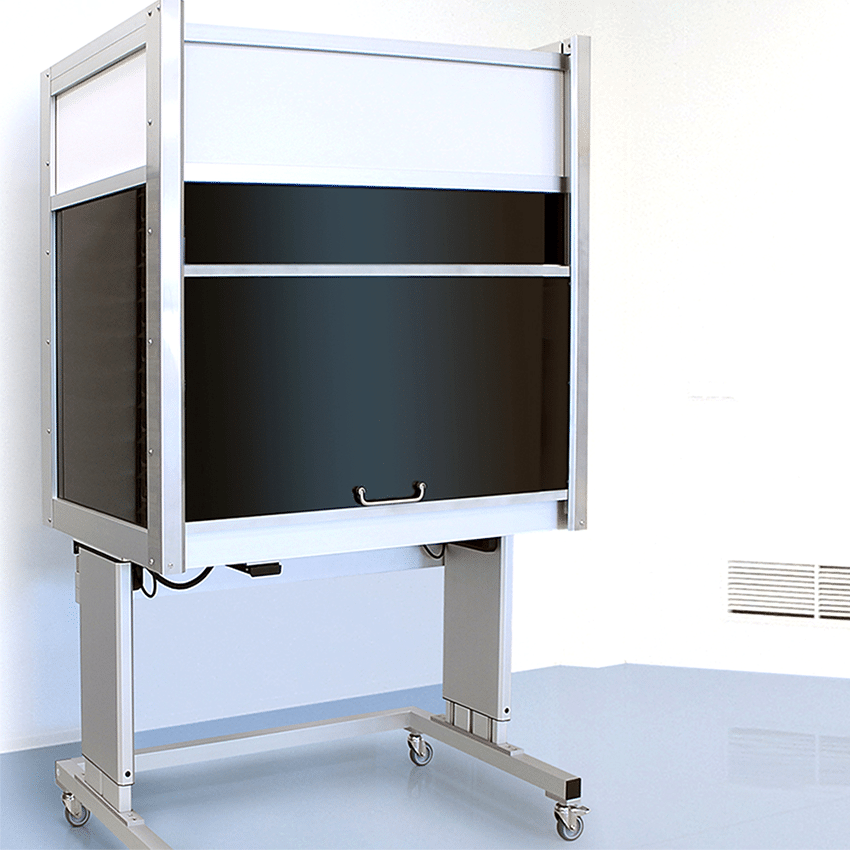

- How cleanliness requirements can be ensured: Clean room, clean room or minienvironment

- Advice on invention requirements and running costs of the individual solutions

- Consultation on qualification and training

Featured on Unchained TV

Unfortunately, there are no use case videos yet for this product. Browse other robotics videos on Unchained TV.

Consulting service according to VDA 19.2

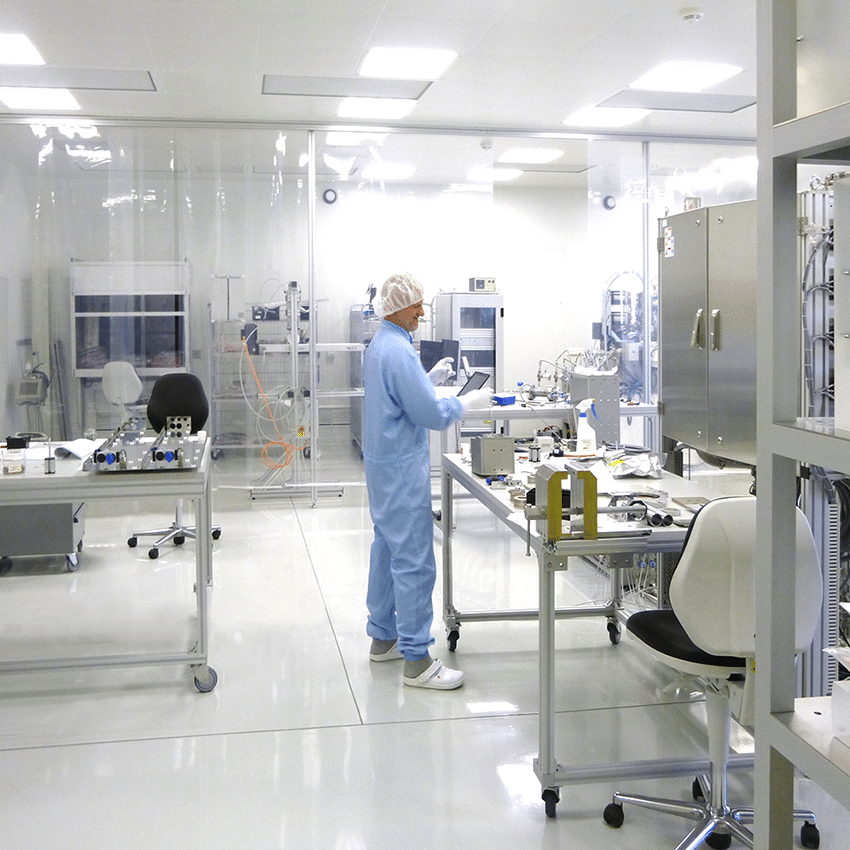

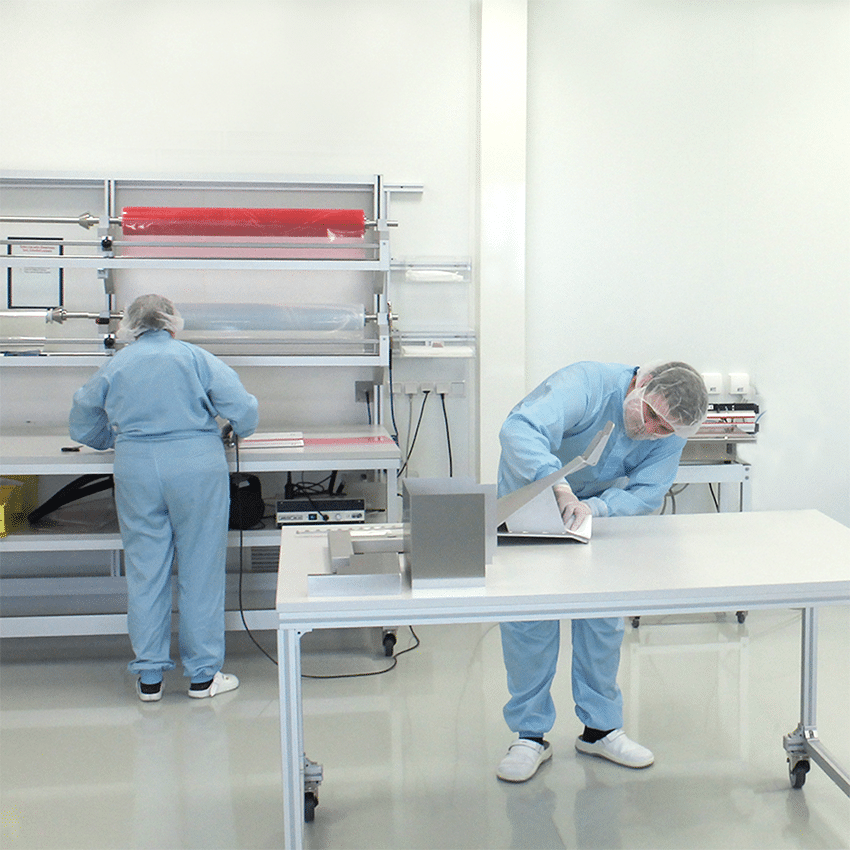

Due to the ever-increasing level of mechanization and automation, undesirable particle contamination in mechanical and electronic assemblies can lead to functional impairments. For more and more industries and production processes, it is therefore important to protect small parts and assemblies from particle contamination and to create controlled environmental conditions.

mkf advises you online or on-site on your individual requirements. In doing so, we support you in carrying out an ACTUAL analysis with the determination of weak points and the development of solution proposals for a reliable realization of the requirements for component cleanliness (according to VDA 19 Part 2).

mkf advises you in the following areas:

Consideration of the spatial environmental conditions

Consideration of the environmental conditions at assembly workplaces

Consideration of the interlinking processes within the clean zone or cleanroom to be created, as well as their interfaces to adjacent areas or areas detached from them.

Our consulting services also include

- Analyze process steps

- Derive cleanliness conditions

- Classification in cleanroom, cleanroom or mini-environment

- Advantages and disadvantages of the mentioned types regarding investment and running costs

- Which rooms must be qualified?

- What does a qualification include?

Available packages:

- 2 x 3 hours online consulting

- 3 x 4 hours online consulting

To place an order, send us an inquiry through the button at the top of the page or contact us through the chat.

Unchained Robotics is the biggest marketplace for all things automation. We have over 36 brands with 9 different categories such as Cobots, Grippers, Cameras, Starter-kits, End-of-Arm-Accessories, Teaching-kits, Turnkey Solution, Cobot-Base and even

Services. For more information, check out our About page.

We have the answer for you in a series of blog post below:

Was du bei der Auswahl eines Cobots beachten solltest – The Specs that Matter

The Specs that Matter Die Top 10 Fragen zur Roboterwahl

Talk to an Automation expert

Have questions about this product, pricing, or your automation projects? Fill out the form and an automation expert from our team will be in touch within 24 hours.

Sebastian Hren

Key Account ManagerWorld Wide

Henning Stoppel

Sales EngineerGermany