Marketplace

Mobile Robots

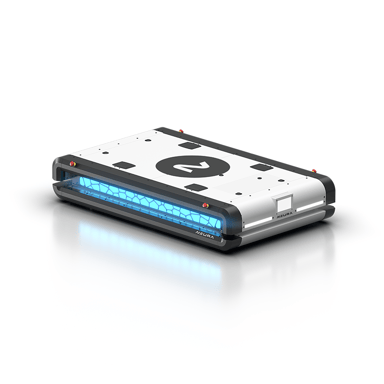

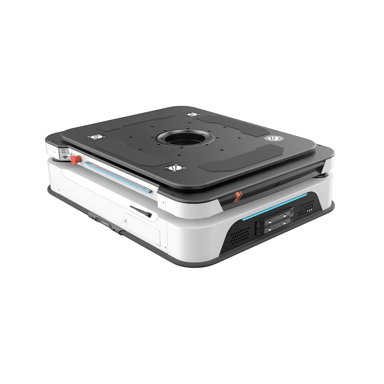

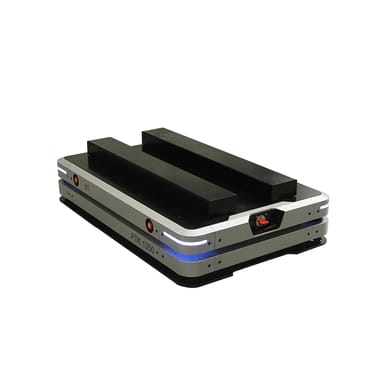

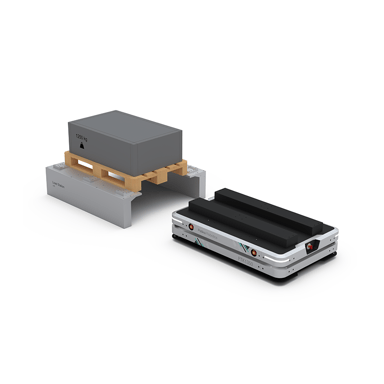

Mobile robots, including Autonomous Mobile Robots (AMRs) and Automated Guided Vehicles (AGVs), automate internal logistics by transporting materials efficiently across warehouses and factories. Unlike stationary robots, these systems navigate dynamic environments—either autonomously or along fixed paths—to streamline material flow and reduce manual handling.

Mobile Robots: Transforming Logistics and Material Flow

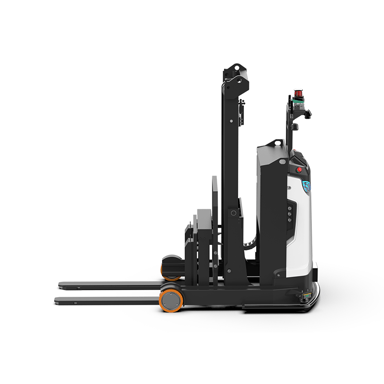

Mobile robots, including Autonomous Mobile Robots (AMRs) and Automated Guided Vehicles (AGVs), streamline logistics by navigating warehouses and factories independently. Unlike industrial robots fixed to tasks like welding or collaborative robots (cobots) built for human teamwork, mobile robots focus on transport, using advanced sensors, AI, and navigation to move materials efficiently. AMRs dynamically adapt to shifting layouts with intelligent pathfinding, while AGVs ensure reliable transport along set routes, handling payloads up to hundreds of kilograms. By integrating seamlessly into intralogistics, these robots cut downtime and boost productivity, revolutionizing material handling.

Advantages of Mobile Robots

Mobile robots excel in flexible, fast-changing environments, unlike the structured setups industrial robots demand. AMRs navigate obstacles autonomously, perfect for dynamic warehouses, while AGVs deliver consistent, high-volume transport in factories. Requiring minimal infrastructure, they reduce installation costs and operate safely in shared spaces without extensive barriers. Their energy-efficient, low-maintenance designs save costs, freeing workers from repetitive transport tasks to focus on higher-value roles, especially in labor-scarce industries.

Programming and Integration

Mobile robots are designed for easy setup, with intuitive software that simplifies route mapping and task assignment, even for non-experts. AMRs use AI-driven systems to learn and adjust paths in real time, while AGVs rely on straightforward programming for fixed routes. Both integrate smoothly with warehouse or factory systems, often working alongside cobots or industrial robots to deliver parts or move finished goods. Accessories like conveyors or lifts enhance versatility, ensuring mobile robots fit seamlessly into diverse automation workflows.

Common Applications of Mobile Robots

Mobile robots transform logistics with tasks like goods transport, inventory handling, and order picking. AMRs thrive in e-commerce, navigating aisles for dynamic picking, while AGVs manage heavy loads in manufacturing, shuttling materials between stations. They complement stationary robots by supplying components to industrial robots or moving products prepared by cobots. From hospital deliveries to retail stocking, mobile robots automate repetitive transport, helping businesses scale efficiently and address supply chain challenges in demanding markets.

Find your automation solution now with our configurator