Marketplace

Laser etching meets automation with GFT Fritze.

High-volume engraving in 2024.

One of GFT-Fritze’s specialties is the laser etching of metal parts. With modern laser machines they are able to achieve very high production volumes – the biggest limiting factor is the worker. The worker still had to manually pick up the parts, put them in a tray, load the tray into the machine, wait, unload, repeat. And that all day long.

Not only is this incredibly boring for the worker, but it also makes little sense in an environment that is so starved for skilled and manual labor. The solution? Automation. And to implement this automation, GFT-Fritze chose Unchained Robotics.

Company:

GFT-Fritze Gravier und Frästechnik

Industry:

Engraving and Machining

Country:

Germany

Solution:

MalocherBot Part Separation

Unchained Robotics specializes in the development and construction of advanced turnkey automation solutions called MalocherBot. And Unchained has exactly the solution for this use case, called MalocherBot Parts Separation.

This solution combines the identification and separation of workpieces with the loading and unloading of the laser etching machine. The operator must simply dump the pieces into the bunker and his work is almost done.

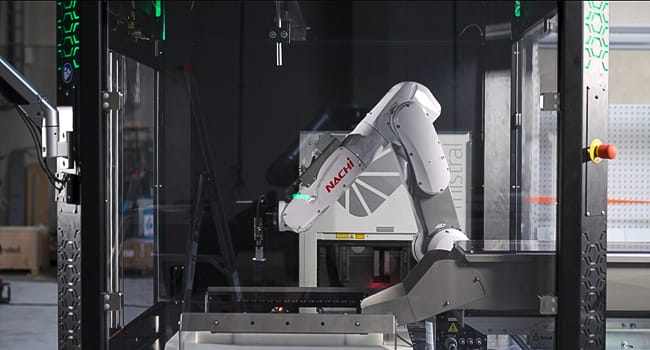

From the RNA Bunker the pieces fall into a Variobotic vibration separator, they are picked up by a NACHI robot and loaded into trays which are then placed in the laser machine. When finished the robot removes the tray, dumps them in the storage receptacle. From here the worker can pick them up after a production run.

Extreme Flexibility and Ease of use with LUNA.

The true innovation of this system however is the software that runs it. MalocherBot is built around Unchained Robotic's advanced Automation Operating System called LUNA. LUNA offers an intuitive user interface that is sea change compared to previous robot interfaces. LUNA allows not only for the easy startup and monitoring of the production run, but it also allows for fast and painless changes to production.

Small changes that in past required a programmer and downtime can now be handled by an operator with minimal training. Error handling and solving is also elegantly bundled into the LUNA Automation OS.

LUNA not only saves GFT-Fritze time and money but also gives them a large degree of independence and autonomy.

Key Features

- Fast ROI

- GFT-Fritze took advantage of the competitive leasing packages available to Unchained Robotics customers, maximizing Return on Investment and saving money from day one.

- Powerful User Interface

- The intuitive interface of the Unchained Robotics LUNA Automation Operating System makes operation, analysis, updates, troubleshooting, and production changes fast and easy.

- Completely Turnkey

- The MalocherBot Part Separation system is shipped ready-to-use, keeping downtime to an absolute minimum.

Cell:

Robot:

Software:

MalocherBot Part Separation

NACHI MZ

Unchained Robotics LUNA Automation OS

Company Profile.

GFT-Fritze Engraving and Milling Technology is a medium-sized company based in Stuhr. The company specializes in the field of engraving and milling technology and offers a wide range of services and products. GFT-Fritze's core competencies lie in the precise processing of various materials using the latest engraving and milling technologies.

The company serves a wide range of industries, including automotive, mechanical engineering and aerospace. With a team of experienced specialists and state-of-the-art machinery, GFT-Fritze is able to carry out complex orders efficiently and to the highest quality. The company places a high value on innovation and continuously invests in the further development of its technologies and processes.

Talk to an Automation expert

Have questions about this product, pricing, or your automation projects? Fill out the form and an automation expert from our team will be in touch within 24 hours.

Sebastian Hren

Key Account ManagerWorld Wide

Henning Stoppel

Sales EngineerGermany

Jens Berg

Sales EngineerGermany