Marketplace

Automated Machine Tending at ELHA Maschinenbau

Leveraging a MalocherBot to fully automate tool machining

Based in Hövelhof, Germany, ELHA Maschinenbau is a versatile machining and engineering company specializing not only in custom CNC construction, but also in the manufacturing of tools and the training of new machinists.

As they were looking to start manufacturing a new hole drill for concrete, the decision was quickly made that the manufacturing process needs to be fully automated from the start. The loading and flipping of incomplete workpieces as well as the unloading of the manufactured parts was all to be automated.

And this is exactly what ELHA achieved with the Unchained Robotics MalocherBot Machine Tending solution!

Company

ELHA-MASCHINENBAU Liemke KG

Industry:

Machinging and CNC machine construction

Country:

Germany

Solution:

MalocherBot Machine Tending (Customized)

We don't need to put our own employees at the machine, who we want to have available for other important tasks.

Manfred Klösner

Project Leader, ELHA Maschinenbau

New Production with Automation from Day 1

When the decision was made to begin manufacturing a new hole drill for concrete at ELHA (with an ELHA CNC Machine system), it was also quickly decided that this line had to be completely automated. Otherwise, it wouldn’t make sense. It was simply neither feasible nor cost-effective to have an operator sitting in front of the machine loading, flipping, and unloading workpieces all day.

Unchained Robotics was then quickly chosen to provide the complete automation solution. One that would allow for long periods of autonomous production on this line so that workers could be occupied in higher value-added tasks elsewhere.

Development and Implementation

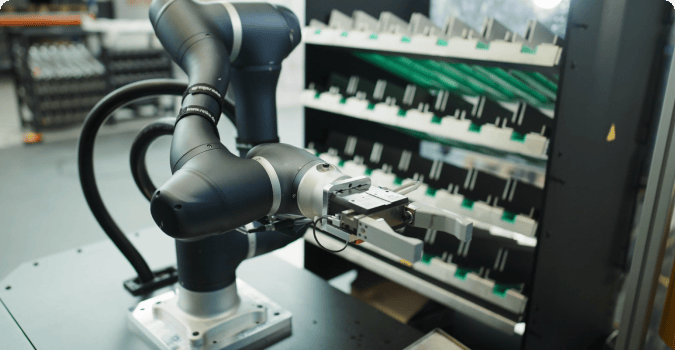

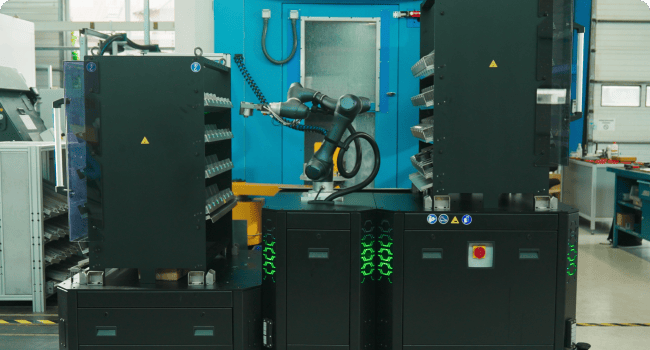

Unchained Robotics offers a wide variety of machine tending solutions as part of its MalocherBot Machine Tending line. As ELHA’s use case is focused on producing only one very specific part for the foreseeable future, we went with a stripped-down MalocherBot Machine Tending S System. This system would load, flip, and unload workpieces in the ELHA CNC Machine whenever the machine told the MalocherBot that it was ready.

The unprepared pieces are stocked on the right side of the system in a large raw material rack. These are loaded at the beginning of the workshift by a worker. Then he presses a button and can move onto other work for the rest of the day. The complete workpieces are unloaded by the MalocherBot system and stored on the left side in the rack for completed products. These can then be unloaded at the end of the day or shift.

Implementation and fully autonomous production

With the implementation of the customized MalocherBot Machine Tending Solution, ELHA managed to build a brand new, almost completely automated production station (partially only because the unprocessed and processed pieces must be loaded into and out of the rack at the end of the production run). Thanks to MalocherBot and ELHA’s forward-thinking approach to new production lines, new tools for workers and craftsmen are being produced right here in Germany with minimal labor costs.

Unchained has professional project management, on the mechanical side, the robotics side and the software side. That's why you can definitely say that the company is absolutely capable of handling complex projects.

Hans-Georg Liemke

CEO, ELHA Maschinenbau

Key Features

Long-term autonomy

Thanks to its built in workpiece storage system, this MalocherBot can work all day with little to no interference or interaction from the operator.

Small footprint

The small footprint of the MalocherBot Machine Tending system allowed for maximal productivity on the shopfloor and no interference with surrounding processes.

Truly Turnkey

The complete solution was delivered and implemented as a turnkey package.

Company Profile

ELHA is famous for customized machining centers, special purpose machinery and production modules. Many industries such as largescale bearing manufacturers, automotive OEM´s and their TIER 1/2 suppliers rely on our experience and technological expertise for developing and realizing of highly productive metal cutting processes as well as our competence for design and production of metal cutting machine tools and turn key solutions.

ELHA’s 240 employees work hard for continuous improvement of product- and service quality in order to ensure reliability and maintainability. Highest customer and employee satisfaction level is the most important subject of our business policy.

ELHA machining systems and turnkey solutions are highly productive, absolutely reliable as well as durable and have an outstanding quality.

Talk to an Automation expert

Have questions about this product, pricing, or your automation projects? Fill out the form and an automation expert from our team will be in touch within 24 hours.

Sebastian Hren

Key Account ManagerWorld Wide

Henning Stoppel

Sales EngineerGermany

Jens Berg

Sales EngineerGermany