Marketplace

Innovative automated Machine Tending with BAUM

When there aren’t enough workers, automation means staying competitive

Based in Büren not far from Paderborn, BAUM is a machining company that can look back on a long tradition of success and innovation. Today, there is more than enough business and plenty of work to do, but finding people who can or want to do the work has become significantly more difficult – in fact, nearly impossible.

In order to remain competitive and to allocate current employees as efficiently as possible, Thomas Baum decided that automation was the way to go. Unchained Robotics was happy to provide a new automation solution for one of Baum’s CNC machines, allowing Baum to not only produce fully automonously for all shifts, but also to continue working overnight. This is non-stop fully automated production thanks to Unchained Robotics’ MalocherBot.

Company:

Baum GmbH

Industry:

Machining Zerspanungstechnik und Werkzeugbau

Country:

Germany

Solution:

MalocherBot Machine Tending

We would recommend Unchained Robotics at any time.

Thomas Baum

CEO, BAUM GmbH

No workers? Meet MalocherBot

As it has become increasingly difficult to find workers and apprentices throughout Germany, Baum GmbH was unfortunately no exception. And despite the difficult labor situation, the pressure to compete with companies outside of Germany and Europe only continues to increase.

The solution: Automation – specifically Unchained Robotic’s MalocherBot Machine Tending. With this advanced and easy-to-use machine tending solution Baum was able to achieve a rapid ROI and increase manufacturing efficiency.

Powerful software and innovative design

Baum had a number of custom needs, from a built-in parts storage system and the ability to push the entire cell out of the way, case it needed to be manually used.

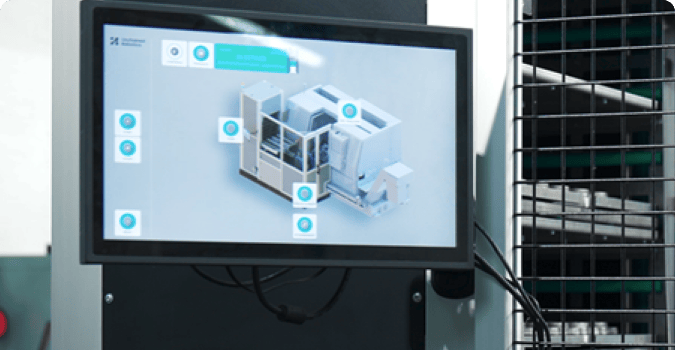

Thankfully the MalocherBot system is designed to allow for customer-specific changes – both on the hardware and software level. Like all MalocherBot systems, the solution is powered by Unchained’s proprietary LUNA Automation Operating System. This system offers an intuitive user interface and the ability for machine operators to operate the system and make production changes – all without extensive training and with no code.

From too few employees to (automated) overnight shifts

The result of the integration of the MalocherBot solution was night and day – literally. Baum GmbH went from having difficulties fielding employees for their normal shift schedule to being able to do overnight, unmanned production runs. With their MalocherBot solution, they can get the absolute max from their CNC machine. With the combination of lower labor costs and longer production times, Baum GmbH is enjoying a lightening-fast return on investment.

The implementation was perfect.

Thomas Baum

CEO, BAUM GmbH

Key Features

Intuitive user interface

Thanks to the LUNA Automation Operating System, the production cell has an intuitive, easy-to-use interface allowing for a quick overview of system and production status, easy access to support, and KPI overviews.

Easy changes to workpieces and process

The cell’s interface and operating system also allow for fast and easy changes to the process or the addition of new workpiece types.

Completely turnkey solution

The complete solution was delivered and implemented as a turnkey package.

Company Profile

Founded in 1961 and located in Büren, Germany, Baum GmbH is a flexible service provider specializing in precision manufacturing. The company produces single parts based on patterns or drawings, as well as small and large series, prototypes, and custom-made products.

With a commitment to maintaining a state-of-the-art machine park, Baum GmbH is equipped with modern turning and milling centers, as well as advanced CAD/CAM systems.

These technologies enable the company to meet the ever-changing demands of its customers.

Baum GmbH collaborates with various industries, including the automotive sector, plant and equipment construction, high-voltage technology, wood industry, plastic processing, mechanical engineering, medical technology, and agricultural engineering.

Talk to an Automation expert

Have questions about this product, pricing, or your automation projects? Fill out the form and an automation expert from our team will be in touch within 24 hours.

Sebastian Hren

Key Account ManagerWorld Wide

Henning Stoppel

Sales EngineerGermany

Jens Berg

Sales EngineerGermany