Marketplace

Packing fragile objects with the RG2-FT gripper - use case

In the video

The first robots were used to handle durable and heavy materials like metal. One of the principle reasons for this was, lacking the tactile feedback of the human hand, it was simply too easy to break fragile items.

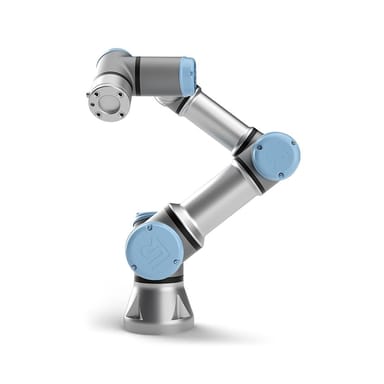

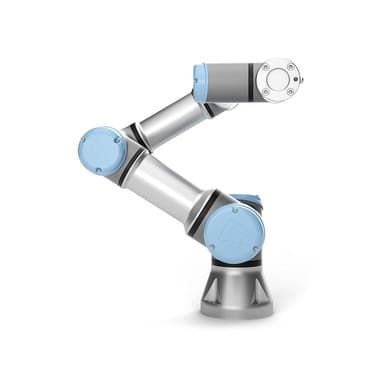

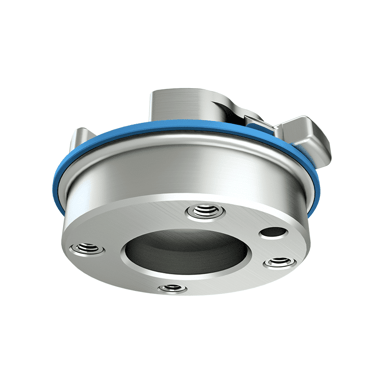

As seen in this modern use case based on a cobot from Universal Robots and an OnRobot RG2-FT, robots have become a lot more sensitive.

Thanks to the force and torque sensors built into the RG2-FT's fingers, the perfect amount of force can be applied to the product, in this case a glass. This way enough force is applied to pick the glass up, but not so much that it is in danger of being broken.

The precise and careful movements of the UR cobot combined with the deterity and controlled force of the RG2-FT combine to create an automated solution that can be applied to any use case involving the handing of smaller, fragile objects.

Share video

You might be interested in...

Pick&Place use cases with the RG2 and RG6 OnRobot grippers.

Easy Pick&Place Automation with a Doosan cobot and the DH Robotics PGC-140 gripper

DH Robotics DH-3 adaptive gripper works with an OMRON TM Cobot

Cobot serves coffee with a DH Robotics AG-95 gripper

A DOBOT robot serves drinks with its DH Robotics PGC-140 gripper

Use cases of the OnRobot VG10 in the packaging sector