Marketplace

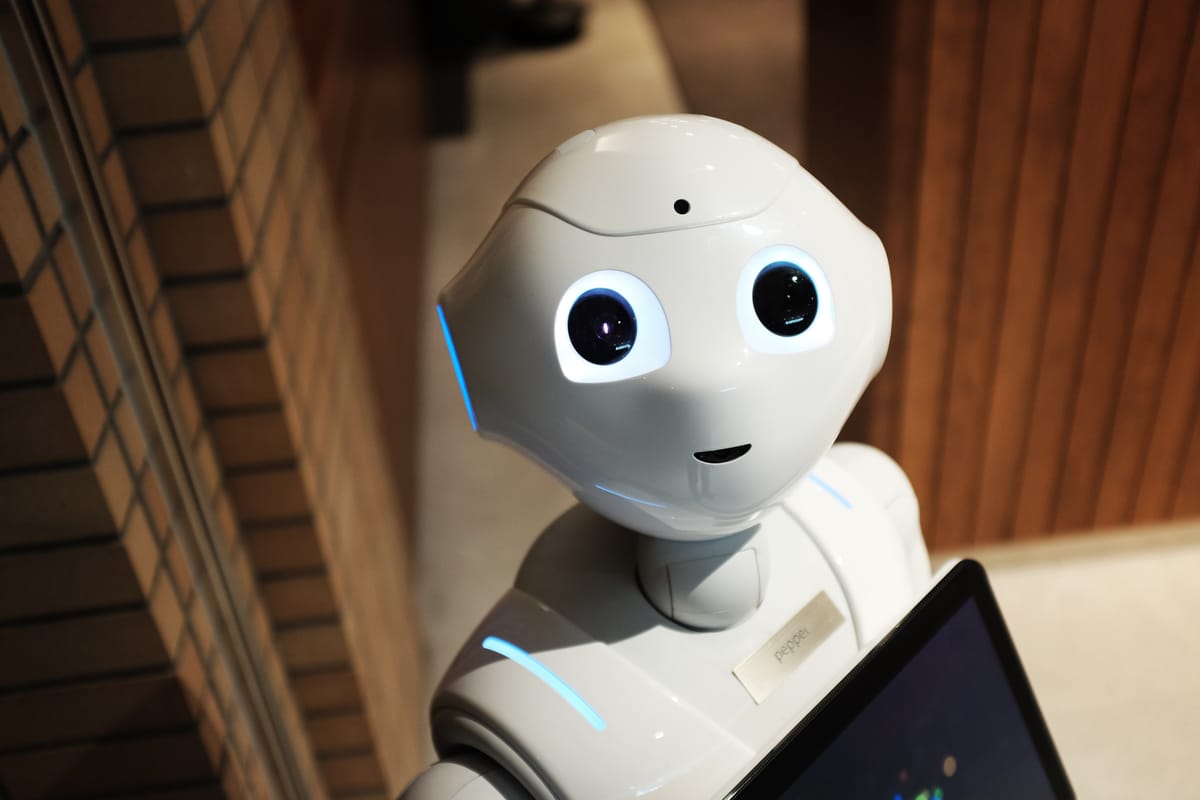

Next-generation Automation for the Automotive Industry of Tomorrow

Automation Solutions for the Automotive Industry

Unchained Robotics offers cobots, cameras, grippers, and pre-built robotic solutions. These solutions are designed to help manufacturers meet tomorrow’s problems today.

Automotive and the next industrial revolution

The automotive industry has always been a frontrunner when it comes to implementing cutting-edge automation technologies. Many of the first industrial robots were installed on automotive manufacturing floors and these lines have grown progressively more automated in the ensuing decades. The next automation revolution has arrived in the form of easy-to-use collaborative robotics, or cobots. These safer, smarter robots are designed to work in conjunction with people, blurring the boundaries between automated and manual processes.

Why Automotive companies need cobots

The benefits of collaborative robots

Safe

Cobots meet strict safety requirements that allow for their utilization in close proximity to people or even work directly with them as part of a hybrid process. This means that the robot can perform more human-like tasks or simply make a current human worker more efficient.

Easy to Integrate

Thanks to this capacity for collaboration, companies in the Automotive industry do not need to completely rebuild their processes and lines around robots themselves. This means that previous investments in machinery can be partially or fully automated without massive changes to the production line or the deprecation recently purchased machinery.

Adaptable

Collaborative robots are in general much easier to program and repurpose than traditional industrial robots, allowing for much greater adaptability. Often, reprogramming a cobot perform a new task on a new line or a new batch is something that any operator can be trained to do. Investments in robots make you more not less agile.

01. Use Case: Screwdriving

Bolting is a common robotic application in the automotive industry and one that can be easily automated with modern technology.

Sample Requirements

Below is an example requirement based on this industry.

15 cm x 20 cm

M4

30 mm

Proposed Solution

Universal Robots UR5e

€30,619.00 excl. VAT.

A compact but powerful cobot from Unviersal Robots

The Universal Robots UR5e is an industry favorite. With a reach of 850 mm and a load capacity of 5 kg, it is ideal for screwdriving applications.

OnRobot Screwdriver

€7,542.00 - €8,984.00 excl. VAT.

Automated screwdriving tool from OnRobot

The OnRobot Screwdriver is an automated screwdriver that can be easily integrated into a large number of common cobots. It can handle a wide range of screw sizes from M1.6 to M6 and up to 50 mm in length. It also offers precise torque control ranging from 0.15 Nm to 5 Nm.

FRAMOS Industrial Depth Camera D435e Starter Kit

A powerful depth camera for machine vision applications

The Framos d435e depth camera has a field of view of 86° x 57° and a working distance of 200-10,000 mm, making it a versatile imaging solution for this bolting application.

Do you have a similar use case?

We are committed to help factories find the right automation solution fit for their case. Simply get in touch with us, tell us about your project, and get free:

consultation

3D simulation

feasibility report

Or, send an email

02. Use Case: Grinding

Grinding is a common task in all industries that shape and machine metal, it is also notoriously monotonous. See how it can be automated in three steps.

Sample Requirements

Below is an example requirement based on this industry.

500 x 500 mm

Tracking

1 min

Proposed Solution

Doosan Robotics M0617

€35,500.00 excl. VAT.

A balance of reach and payload

With a payload of 6 kg and a reach of 1700 mm, the Doosan M0617 combines a long reach with a considerable payload. This is an ideal combination for grinding applications and allows great flexibility in terms of the surface area of the workpiece to be ground.

OnRobot Sander

€3,288.00 - €7,783.00 excl. VAT.

Fast, easy and flexible automated grinding

The OnRobot Sander is an end-of-arm tool for grinding and polishing applications. Its user-friendly software and optional automatic grit changer make it an ideal solution for grinding automation.

A strong foundation for automation

The ibk CobotBase provides an excellent foundation for a grinding solution. The CobotBase minimizes the footprint of the cobot and maximizes stability.

Do you have a similar use case?

We are committed to help factories find the right automation solution fit for their case. Simply get in touch with us, tell us about your project, and get free:

consultation

3D simulation

feasibility report