Marketplace

Weld removal without code with Nordbo sensor and a cobot from Universal Robots

In the video

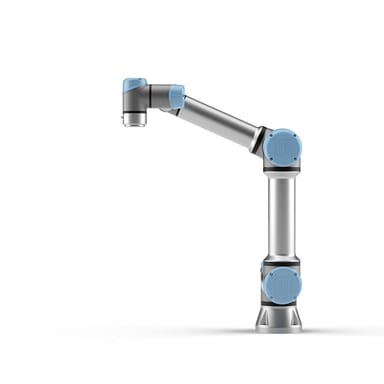

In this example use case we a see a Nordbo Robotics torque sensor and a cobot from Universal Robots combined to create a powerful seam removal solution.

With Nordbo's innovative tech, this can even be implemented in a "No Code" fashion. With easy, code-less teaching, the robot can be far more easily redeployed and reprogrammed.

This makes such a set up ideal for high mix/low volume environments.

Add a Sander from OnRobot to complete the entire set up!

Share video

You might be interested in...

Surface cleaning with the OnRobot HEX force/torque sensor

Sanding and polishing a car door with the Nordbo Mimic Kit and a UR Cobot

Surface treatment with Nordbo Mimic Kit and torque sensor + cobot from Universal Robots

Fast tool change with Nordbo's magnetic tool changer and a UR Cobot

Removing parting lines with the OnRobot HEX force/torque sensor and RG2 gripper

Deburring without code with the Nordbo Mimic Kit and a UR Cobot

Automated polishing with the Nordbo Mimic Kit and a cobot from Universal Robots

Deburring with the OnRobot HEX force-moment sensor