Marketplace

Fast tool change with Nordbo's magnetic tool changer and a UR Cobot

Most processes are multi-step and require a variety of tools. Generally, a robot will only have one tool attached to the arm, greatly limiting the number of tasks it can perform.

Instead of using a second robot, an automatic tool changing system, like the Nordbo Magnetic Tool Changer, can be implemented and allow the robot to perform multiple disparate tasks. The Magnetic Tool Changer allows a robot to use two or more tools and quickly change between them.

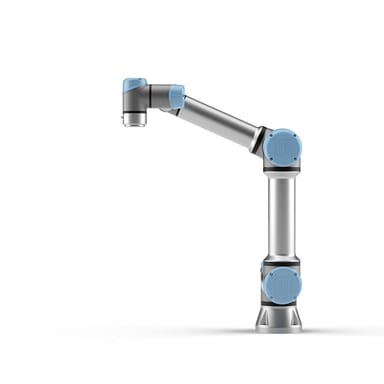

In this example use case, a cobot from Universal Robots is decked out with the Nordbo Magnetic Tool Changer, allowing the robot to easing switch between two different tools. With access to a larger variety of tools, the Universal Robots cobot can achieve much more!

Share video

You might be interested in...

A DOBOT CR5 Cobot and an M1 SCARA Robot deftly handle assembly and unloading tasks.

OMRON cobots give transmission manufacturer Fischer a competitive edge in production

Surface cleaning with the OnRobot HEX force/torque sensor

Polishing wood and metal parts with the OnRobot HEX force torque sensor

Collaborative machine operation with the Kassow Robots KR810

Weld removal without code with Nordbo sensor and a cobot from Universal Robots

24/7 automated laser marking with Kassow Robots and OnRobot

Fast tool change with Nordbo's magnetic tool changer and a UR Cobot

Deburring with the OnRobot HEX force-moment sensor

Weld seam removal with Nordbo Robotics and a cobot from AUBO Robotics

Pin insertion with the OnRobot RG2-FT gripper

Grinding and polishing with the OnRobot Sander and a Cobot from Universal Robots

Sanding and polishing a car door with the Nordbo Mimic Kit and a UR Cobot

Assembly with the OnRobot HEX force torque sensor and RG2 gripper

Automation of machine operation with Kassow Robots