Marketplace

Collaborative machine operation with the Kassow Robots KR810

Machine tending is a common and often very repetitive process in the modern manufacturing environment. Thankfully, these processes can often be relatively easily automated with modern collaborative tools.

In this video we see a real world use case on a factory floor where a cobot from Kassow Robots is being used in a machine tending process together with a human coworker.

This is a particularly good example of human-machine collaboration.

With their robust joints and 7 degrees of freedom, Kassow Robots offers a powerful solution to many automation problems.

Share video

You might be interested in...

24/7 automated laser marking with Kassow Robots and OnRobot

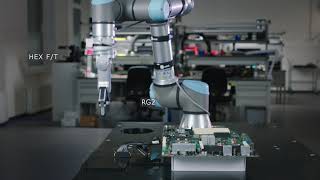

Assembly with the OnRobot HEX force torque sensor and RG2 gripper

Innovative use of OMRON cobots improves safety at Leica Geosystems

Connector assembly with the OnRobot HEX force torque sensor and RG2 gripper

Pin insertion with the OnRobot RG2-FT gripper

DOBOT CR10 tackles a machine tending task with semiconductors

Flexible production through automation with OMRON Cobots

Collaborative machine operation with the Kassow Robots KR810