Marketplace

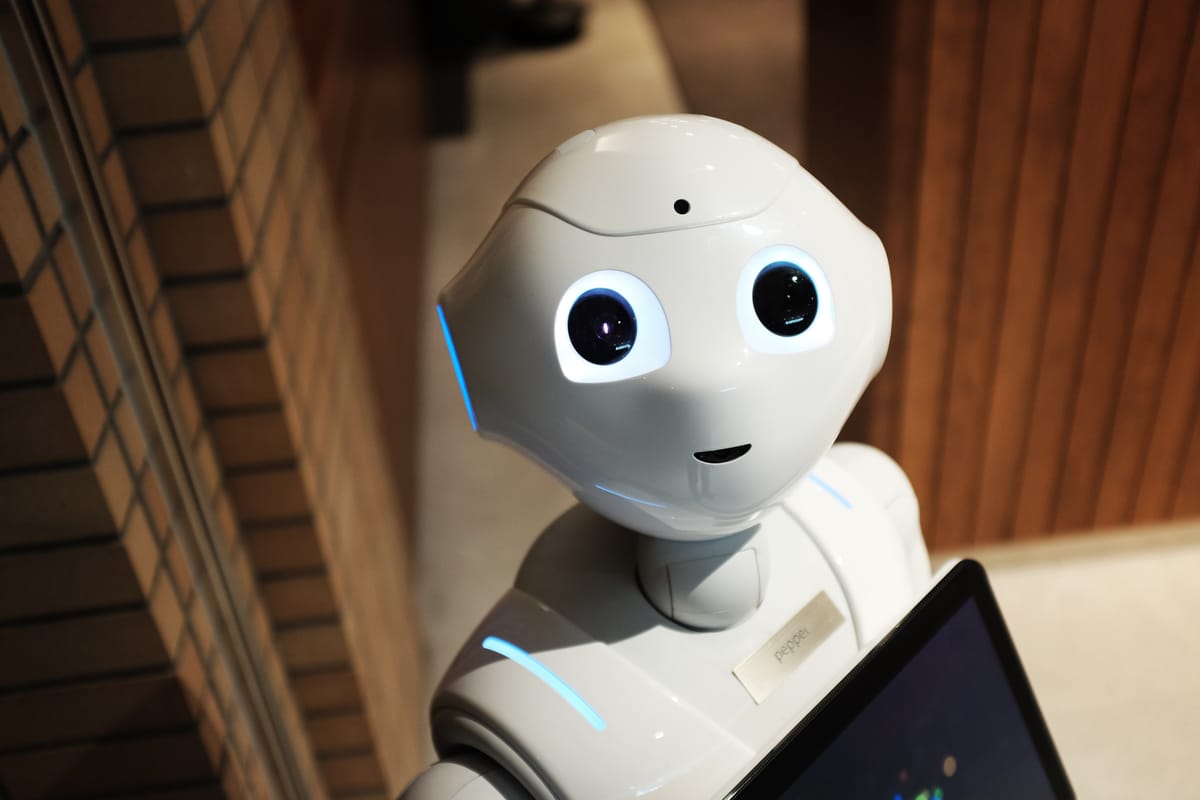

Building the next generation of pharmaceutical production with intelligent automation

Automation solutions for the pharmaceutical industry

Unchained Robotics offers a wide range of robots, grippers, cameras and prefabricated robotic solutions. Unchained can automate packaging, quality control, palletizing and other processes to stay ahead of the competition.

Safer, better and faster production through automation

Collaborative robotics is bringing the next wave of automation to the pharmaceutical industry. This is an industry that demands precision and adherence to strict safety standards. Thankfully, precise, accurate actions are exactly the forte of today’s automation solutions. But unlike those of the previous decades, today’s collaborative automation solutions are smart and safe to work around. Common processes such as loading, palletizing, depalletizing, and product inspection can all be automated with relative ease thanks to modern robotics. Collaborative robots (cobots) in particular are an attractive option because their focus on safety allow them to be operated in the vicinity of people – or even work directly with them. This breaks down the barrier between man and machine and allows for greater efficiencies on the floor. Easy to program and reprogram, a collaborative robot can be moved from line to line with little difficulty and repurposed for a new task with ease, making any pharmaceutical factory more agile and adaptive.

Why pharmaceutical companies need cobots

The advantages of the next generation of robotics

Safe

Cobots meet strict safety requirements that allow for their utilization in close proximity to people or even work directly with them as part of a hybrid process. This means that the robot can perform more human-like tasks or simply make a current human worker more efficient.

Easy to Integrate

Thanks to this capacity for collaboration, companies in the Pharmaceutical Industry do not need to completely rebuild their processes and lines around robots themselves. This means that previous investments in machinery can be partially or fully automated without massive changes to the production line or the deprecation recently purchased machinery.

Adaptable

Collaborative robots are in general much easier to program and repurpose than traditional industrial robots, allowing for much greater adaptability. Often, reprogramming a cobot perform a new task on a new line or a new batch is something that any operator can be trained to do. Investments in robots make you more not less agile.

01. Use Case: Palletizing

Palletizing is a very common use case in the pharmaceutical industry and can also be easily automated with modern tools from Unchained.

Sample Requirements

Below is an example requirement based on this industry.

50x20x30 cm

14 kg

70

Proposed Solution

Doosan Robotics H2515

€50,500.00 excl. VAT.

A powerful cobot with reach

With a reach of 1,500 mm and a payload of 25 kg, the Doosan H2515 is an ideal and extremely powerful and adaptable cobot.

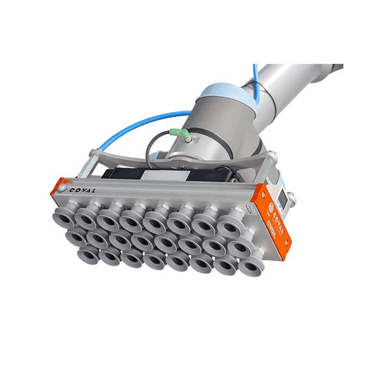

Coval CVGL

€2,958.73 excl. VAT.

A powerful electric vacuum gripper, perfect for palletizing boxes

The VGP20 is an electrically powered vacuum gripper. By using an electrically generated vacuum, this gripper allows for much easier setup and lower maintenance costs compared to a conventional pneumatic gripper.

ifm O3D Camera

€1,513.60 excl. VAT.

A reliable and affordable 3D camera

With a working distance of 300 to 10,000 mm, the IFM O3D is an ideal camera for vision-based palletizing. By using a camera instead of a conventional sensor, the palletizing solution can be reprogrammed and reused much more easily.

Do you have a similar use case?

We are committed to help factories find the right automation solution fit for their case. Simply get in touch with us, tell us about your project, and get free:

consultation

3D simulation

feasibility report