Marketplace

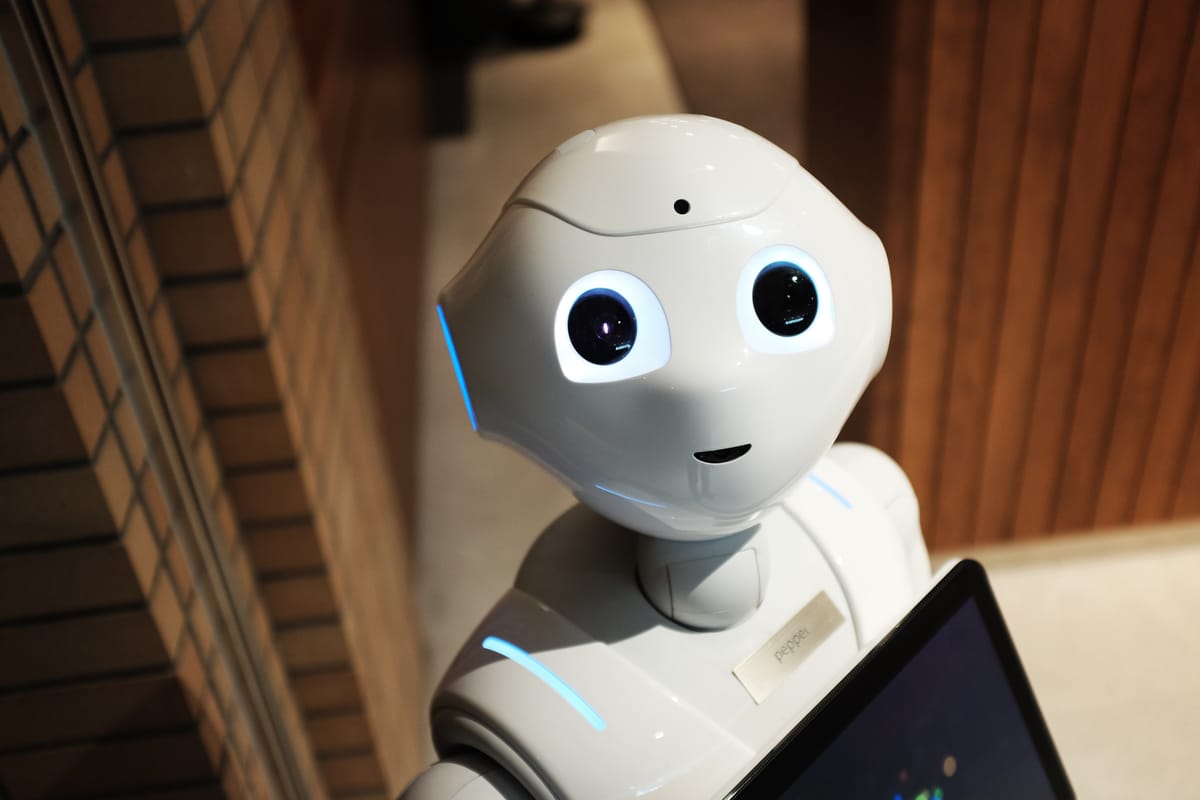

Safer, faster, and more competitive through automation

Automation solutions for modern metalworking

Unchained Robotics provides a multitude of products and solutions for the metalworking industry. From machine tending to grinding to quality inspection, Unchained Robotics makes automation accessible. Discover pre-built and customizable solutions today.

Winning in a globalized world through effective automation

High labor costs, stricter safety standards, and increasing competition have created an environment where only the agile can survive and thrive. Thanks to automation, many in the metal working industry have been rising to the occasion. Robotics allows for not only greater throughput at lower cost but can also make the workplace significantly safer. Correctly, implemented Robotics can vastly increase productivity and thereby greatly reduce relative total cost. For the metalworking industry, like so many others, robotics is the key to being competitive in a globalized world.

Why the metal industry needs to keep an eye on cobots

The advantages of the next generation of robotics

Safe

Cobots meet strict safety requirements that allow for their utilization in close proximity to people or even work directly with them as part of a hybrid process. This means that the robot can perform more human-like tasks or simply make a current human worker more efficient.

Easy to use

Thanks to this capacity for collaboration, companies in the metal industry do not need to completely rebuild their processes and lines around robots themselves. This means that previous investments in machinery can be partially or fully automated without massive changes to the production line or the deprecation recently purchased machinery.

Adaptable

Collaborative robots are in general much easier to program and repurpose than traditional industrial robots, allowing for much greater adaptability. Often, reprogramming a cobot perform a new task on a new line or a new batch is something that any operator can be trained to do. Cobots make factories more agile and responsive to market changes.

01. Use Case: Grinding

Grinding is a common application in the metal industry and one that can be easily automated with today’s automation technology.

Sample Requirements

Below is an example requirement based on this industry.

50 mm x 70 mm

700 g

3 Teile pro Minute

Proposed Solution

A reliable robot employee

With a reach of 915 mm and a payload of 5 kg, Hanwha’s HCR-5A is a mid-sized cobot ideal for CNC machine tending applications.

OnRobot 3FG15

€4,630.00 - €6,072.00 excl. VAT.

Electric 3-finger gripper with large stroke for handling a wide range of cylindrical objects

The Onrobot 3FG15, with a maximum stroke of 150 mm, can easily handle cylindrical objects from 20 mm to 150 mm. In a setup with an OnRobot Dual QuickChanger, a powerful CNC machine tending solution can be set up. One gripper removes the finished part from the machine, the other inserts a new one.

A mobile and implementable solution

With the ibk CobotWagen, an automation solution can be easily moved from workstation to workstation, saving time and money. The cart is easy to lock in place and provides a very stable base for the robot to work on.

Do you have a similar use case?

We are committed to help factories find the right automation solution fit for their case. Simply get in touch with us, tell us about your project, and get free:

consultation

3D simulation

feasibility report

Or, send an email

Grinding

02. Use Case: Grinding

Grinding is a common task in all industries that shape and machine metal, it is also notoriously monotonous. See how it can be automated in three steps.

Sample Requirements

Below is an example requirement based on this industry.

500 x 500 mm

Tracking

1 min

Proposed Solution

Doosan Robotics M0617

€35,500.00 excl. VAT.

A balance of reach and payload

With a payload of 6 kg and a reach of 1700 mm, the Doosan M0617 combines a long reach with a considerable payload. This is an ideal combination for grinding applications and allows for superior flexibility.

OnRobot Sander

€3,288.00 - €7,783.00 excl. VAT.

Fast, easy and flexible automated grinding

The OnRobot Sander is an end-of-arm tool for grinding and polishing applications. Its user-friendly software and optional automatic grit changer make it an ideal solution for grinding automation.

A strong foundation for automation

The ibk CobotBase provides an excellent basis for a possible grinding solution. The CobotBase minimizes the footprint of the cobot and maximizes stability.

Do you have a similar use case?

We are committed to help factories find the right automation solution fit for their case. Simply get in touch with us, tell us about your project, and get free:

consultation

3D simulation

feasibility report