Marketplace

Meeting the Challenges of Tomorrow with Automation Today

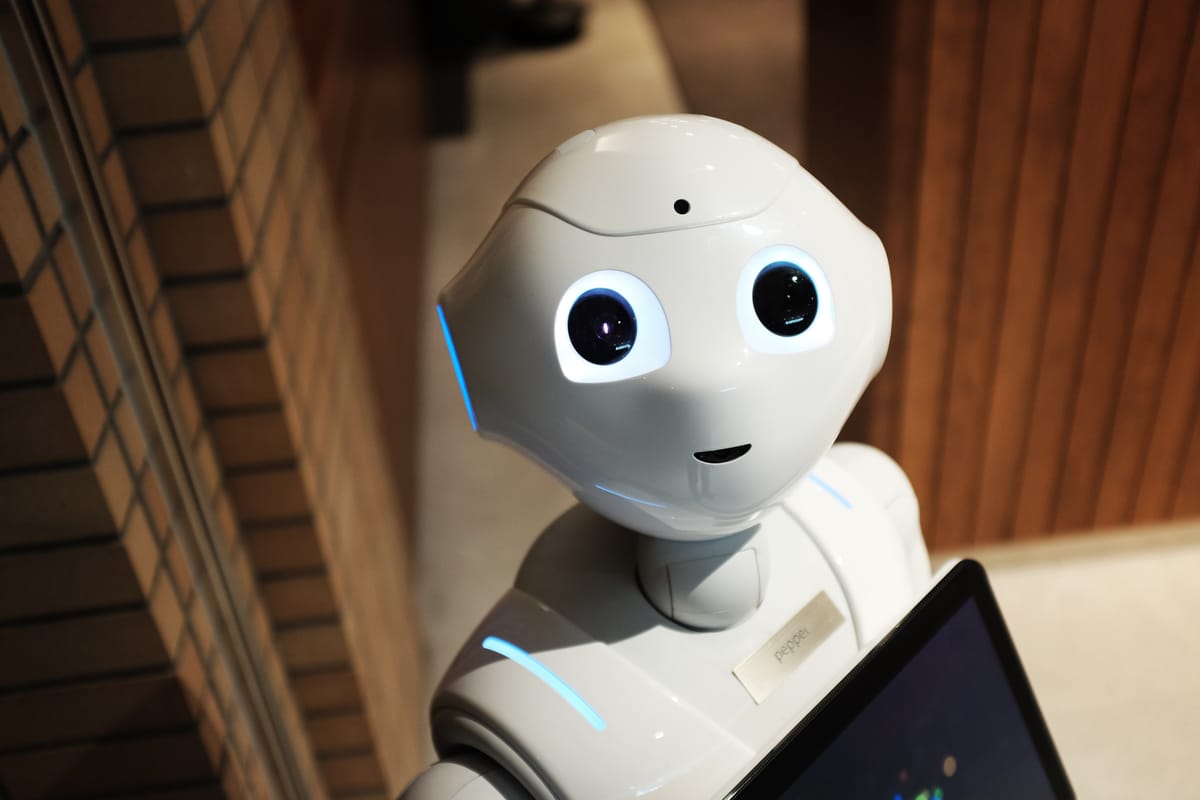

Advancing Automation in the Food Industry

Unchained Robotics offers a wide range of robots, grippers, cameras and complete starter kits to suit any industry. Pick and place, palletizing, quality control and more can be automated today. Don’t wait to automate – robotics has never been easier or more user-friendly.

The automation revolution and food

The food industry was a pioneer in mechanization but has been a little bit slower on the uptake with automation. This is largely because so much of the work done in the food industry was simply too hard to automate. The objects were either too fragile or required manipulation that robots couldn’t do. But this is no longer the case. Thanks to modern automation techniques, collaborative robots, and a myriad of advances in robotics, many food industry processes can now be wholly or partially automated. In an increasingly complicated and globalized market marked by unpredictability and labor shortage, this allows business in the food industry to gain an edge.

Collaborative Robots in the Food Industry

The advantages of collaborative robots

Safe

Cobots meet strict safety requirements that allow for their utilization in close proximity to people or even work directly with them as part of a hybrid process. This means that the robot can perform more human-like tasks or simply make a current human worker more efficient.

Easy to Integrate

Thanks to this capacity for collaboration, companies in the food industry do not need to completely rebuild their processes and lines around robots themselves. This means that previous investments in machinery can be partially or fully automated without massive changes to the production line or the deprecation recently purchased machinery.

Adaptable

Collaborative robots are generally much easier to program and reprogram than traditional industrial robots. This in turn allows for much greater adaptability. Reprogramming a robot for a new task on a new line or for a new batch is often something that any operator can be trained to do. Investing in robots makes you more, not less, agile.

01. Use Case: Pick and Place

Collaborative robots are in general much easier to program and repurpose than traditional industrial robots, allowing for much greater adaptability. Often, reprogramming a cobot perform a new task on a new line or a new batch is something that any operator can be trained to do. Investments in robots make you more not less agile.

Sample Requirements

Below is an example requirement based on this industry.

100 g

5 cm x 5 cm

5 packages per minute

Proposed Solution

Omron TM5-700

€30,320.00 excl. VAT.

A powerful collaborative robot from Omron

With a reach of 700 mm and a payload of 6 kg, this cobot is ideal for Pick and Place applications in fruit handling.

OnRobot VGC10

€3,206.00 - €4,648.00 excl. VAT.

A compact and adaptable Electric Vacuum Gripper

This compact gripper is perfect for small spaces and smaller robotic arms, while having an impressive payload. Despite its compact size, this gripper tool can lift up to 15 kg.

OnRobot Eyes

€6,371.00 excl. VAT.

A flexible and customizable 2.5D vision system

The OnRobot Eyes camera, based on Intel RealSense technology, enables easy and consistent food identification and placement.

Do you have a similar use case?

We are committed to help factories find the right automation solution fit for their case. Simply get in touch with us, tell us about your project, and get free:

consultation

3D simulation

feasibility report

Or, send an email

02. Use Case: Palletizing

Palletizing is a very common application in the food industry and can also be easily automated with advanced and easy-to-use tools from Unchained.

Sample Requirements

Below is an example requirement based on this industry.

50x20x30 cm

14 kg

70

Proposed Solution

Doosan Robotics H2515

€50,500.00 excl. VAT.

A powerful cobot with reach

With a reach of 1,500 mm and a payload of 25 kg, the Doosan H2515 is an extremely powerful and adaptable cobot.

OnRobot VGP20

€5,333.00 - €6,853.00 excl. VAT.

Powerful electric vacuum gripper, ideal for palletizing cartons

The VGP20 is an electrically driven vacuum gripper. By using an electrically generated vacuum, this gripper allows for much easier setup and lower maintenance costs compared to a conventional pneumatic gripper.

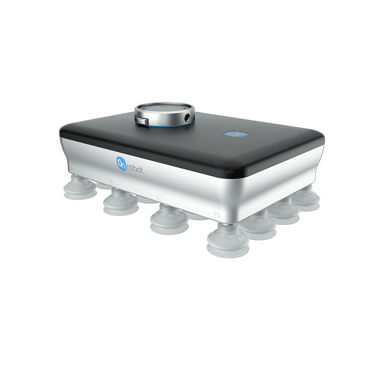

ifm O3D Camera

€1,450.50 excl. VAT.

A reliable and affordable 3D camera

With a working distance of 300 to 10,000 mm, the IFM O3D is an ideal camera for vision-based palletizing. By using a camera instead of a conventional sensor, the palletizing solution can be reprogrammed and redeployed much more easily.

Do you have a similar use case?

We are committed to help factories find the right automation solution fit for their case. Simply get in touch with us, tell us about your project, and get free:

consultation

3D simulation

feasibility report